Umkhiqizi Wezibuthe Wesiteshi Se-Neodymium | Osayizi Bangokwezifiso nama-oda Enqwaba avela e-China

Umkhiqizi we-OEM waseChinaabasebenza ngozibuthe besiteshi be-neodymium abasebenza kahle kakhulu, banikeza osayizi bangokwezifiso (kuhlanganise nozibuthe bamabhulokhi) namandla kazibuthe (afika ku-N52) anemiphetho egqize nge-nickel noma ehlanganiswe ngensimbi. Ozibuthe bethu besiteshi esindayo baletha amandla okudonsa aphakeme namandla okubamba uma kuqhathaniswa nezinye izindlela zobumba, abafaka izizibuthe ezithuthukisiwe zezinhlelo zokusebenza zezimboni. Sisekela ama-oda ayinqwaba ngokuletha ngokushesha, sihlinzeka nge-ODM/OEM epheleleizixazululo ezihlanganisa iziteshi zensimbi zensimbifuthi simiklamo ehambisana nabasebenzi yezinhlelo zokukhweza ezivikelekile.

Amasampuli Wezibuthe Wethu Neodymium

Sihlinzeka ngezinhlobonhlobo zamasampula kazibuthe wesiteshi ngobukhulu obuhlukene, amamaki (I-N35–N52), kanye nama-coatings. Ungacela isampula yamahhala ukuze uhlole amandla kazibuthe futhi ulingane ngaphambi kokufaka ama-oda amaningi.

omagnethi besiteshi se-neodymium

omaginethi besiteshi se-neodymium

i-neodymium magnets hydraulic press press channel

Cela Isampula Yamahhala - Hlola Ikhwalithi Yethu Ngaphambi Kwe-oda Yenqwaba

Ozibuthe Besiteshi Sangokwezifiso Neodymium – Umhlahlandlela Wenqubo

Inqubo yethu yokukhiqiza imi kanje: Ngemva kokuba ikhasimende linikeze imidwebo noma izidingo ezithile, ithimba lethu lonjiniyela lizobuyekeza futhi liziqinisekise. Ngemva kokuqinisekisa, sizokwenza amasampula ukuze siqinisekise ukuthi yonke imikhiqizo ihlangabezana namazinga. Ngemuva kokuqinisekiswa kwesampula, sizokwenza ukukhiqiza ngobuningi, bese sipakisha bese sithumela ukuze siqinisekise ukulethwa okuphumelelayo nokuqinisekiswa kwekhwalithi.

I-MOQ yethu ingu-100pcs, singahlangabezana nokukhiqizwa kwenqwaba yamakhasimende amancane kanye nokukhiqizwa kwenqwaba enkulu. Isikhathi esijwayelekile sokufakazela siyizinsuku ezingama-7-15. Uma kukhona isitokwe sikazibuthe, ukuhlolwa kungaqedwa. phakathi kwezinsuku ezingu-3-5. Isikhathi sokukhiqiza esijwayelekile sama-oda amaningi yizinsuku eziyi-15-20. Uma kukhona i-inventory kazibuthe kanye nama-oda wokubikezela, isikhathi sokulethwa singathuthukiswa sibe yizinsuku ezingaba ngu-7-15.

Iyini i-Neodymium Channel Magnet?

Umazibuthe wesiteshi ubhekisela ekuhlanganiseni kazibuthe lapho omagnethi be-neodymium (NdFeB) bashumekwe eziteshini zensimbi noma ze-aluminium. Lezi zibuthe zeziteshi zomhlaba eziyivelakancane zihlanganisa amandla adlulele ebanga le-N35-N52 neodymium nokusekelwa kwesakhiwo kwezicelo zezimboni.

Ilungele amasistimu okukhweza, izinzwa, nezisetshenziswa ezizenzakalelayo ezidinga amandla kazibuthe nokuvikelwa komshini.

Izicelo Neodymium Channel Magnets

Inqubo Yokukhiqiza Magnet Yesiteshi Se-Neodymium Nokulawulwa Kwekhwalithi

I-Sintering → Ukusika/Ukukhanda → Ukwenza uMazibuthe → Ukugqoka → Ukupakisha

Kungani Usikhethe Njengomkhiqizi Wezibuthe Wesiteshi Sakho I-Neodymium Magnet?

Njengefekthri yomkhiqizi kaMagnet, sineFactory yethu ezinze e-China, futhi singakuhlinzeka ngezinsizakalo ze-OEM/ODM.

Ukusebenza okuphezulu kwe-neodymium impahla:I-N35–N52 ngokukhetha, isekela izinga lokushisa eliphezulu kanye ne-anti-corrosion coating (i-nickel plating, i-epoxy, njll.).

Ukuvumelana nezimo ngokwezifiso:usayizi/i-coating/magnetizing direction/logo konke kungenziwa ngezifiso.

Umuzwa ocebile wokuthekelisa:Inani elikhulu leqoqo elithunyelwa eYurophu, eMelika, eJapan, eNingizimu Korea, ePakistan, eMpumalanga Ephakathi, njll.

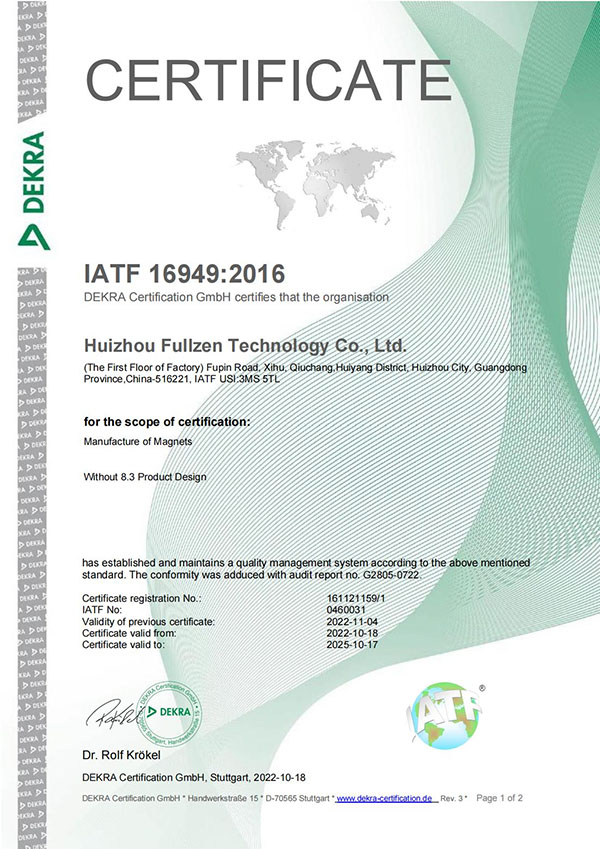

IATF16949

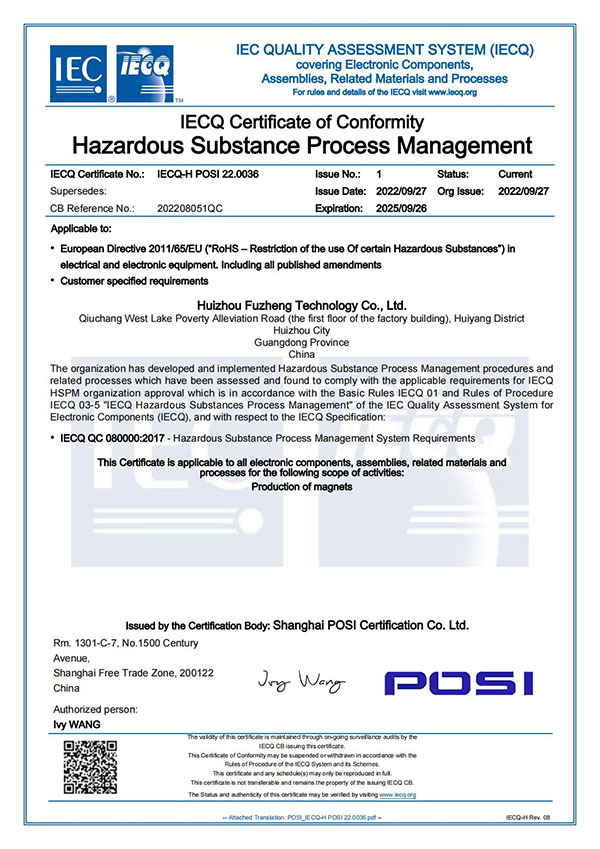

I-IECQ

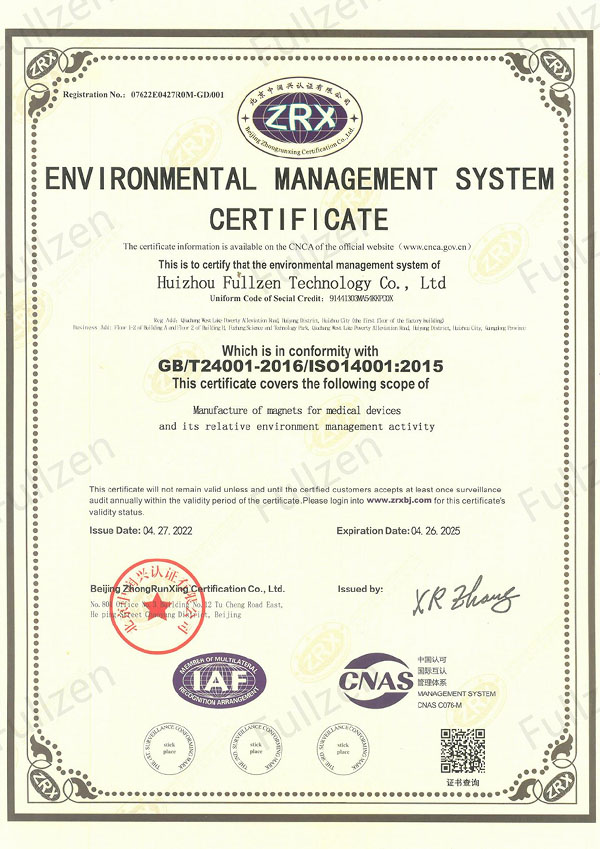

ISO9001

ISO13485

I-ISOIEC27001

SA8000

Izixazululo Ezigcwele Ezivela Kumakhi Wezibuthe We-Neodymium

I-Fullzen Technology ikulungele ukukusiza ngephrojekthi yakho ngokuthuthukisa nokukhiqiza i-Neodymium Magnet. Usizo lwethu lungakusiza uqedele iphrojekthi yakho ngesikhathi futhi ngaphakathi kwesabelomali. Sinezixazululo eziningana zokukusiza uphumelele.

Ukuphathwa Kwabahlinzeki

Ukuphathwa kwethu okuhle kakhulu kwabahlinzeki kanye nokulawula uchungechunge lokuhlinzeka kungasiza amakhasimende ethu ukuthi athole ukulethwa okusheshayo nokunembile kwemikhiqizo yekhwalithi.

Ukuphatha Ukukhiqiza

Zonke izici zokukhiqiza zisingathwa ngaphansi kokuqondisa kwethu ngekhwalithi efanayo.

Ukuphathwa Kwekhwalithi Eqinile Nokuhlola

Sinethimba lokuphatha ikhwalithi eliqeqeshwe kahle nelinochwepheshe (Ukulawulwa Kwekhwalithi). Baqeqeshelwe ukuphatha izinqubo zokuthengwa kwezinto ezibonakalayo, ukuhlolwa komkhiqizo oqediwe, njll.

Isevisi yangokwezifiso

Asikunikezi kuphela izindandatho ze-magsafe zekhwalithi ephezulu kodwa futhi sikunikeze ukupakishwa nokusekelwa ngokwezifiso.

Ukulungiselela Idokhumenti

Sizolungisa amadokhumenti aphelele, njengebhili yezinto ezibonakalayo, i-oda lokuthenga, uhlelo lokukhiqiza, njll., ngokuya ngezidingo zakho zemakethe.

I-MOQ efinyelelekayo

Singahlangabezana nezidingo ze-MOQ zamakhasimende amaningi, futhi sisebenze nawe ukuze senze imikhiqizo yakho ihluke.

Imininingwane yokupakisha

Qala Uhambo Lwakho lwe-OEM/ODM

Imibuzo Evame Ukubuzwa mayelana Nezibuthe Zesiteshi Neodymium

Yebo, sisekela amasampula wamahhala ukuze kuthuthukiswe amakhasimende ethu.

Isikhathi esijwayelekile sokulethwa kwama-oda e-Bulk yizinsuku eziyi-15-20, kodwa uma ungakwazi ukunikeza uhlelo lwesibikezelo ngaphambi kokufaka i-oda noma uma sinesitoko, usuku lokulethwa lungathuthukiswa.

Ozibuthe be-NdFeB abakwazi ukumelana nokushisa njengozibuthe be-Alnico, abakwazi ukumelana nezinga lokushisa elingu-450 kuya ku-550 °C. Omazibuthe be-NdFeB ngokuvamile bamelana namazinga okushisa acishe abe ngu-80 kuya ku-220°C.

Singahlinzeka nge-zinc enamathela, i-nickel enamathela, i-nickel yamakhemikhali, i-zinc emnyama ne-nickel emnyama, i-epoxy, i-epoxy emnyama, i-golden coating njll ...

Inkambu kazibuthe yesimo ngasinye sikazibuthe sihlukile. Singakwazi ukwenza ngendlela oyifisayo umumo nesiqondisindlela sokusebenza uzibuthe ukuze sihlangabezane nezidingo zekhasimende.

Ulwazi Lochwepheshe & Umhlahlandlela Wokuthenga Wabathengi Bezimboni

I-Mechanism of Groove Structure in Magnetic Field Concentration and Force Envelopment

●I-Magnetic Field Concentration: Izakhiwo ezimile zingagxilisa imigqa yakazibuthe eduze nezikhala, zehlise ukuhlakazeka futhi zidale indawo kazibuthe eqinile yendawo.

● Amandla Amagnetic Athuthukisiwe: Imiphetho yezikhala ikhiqiza inkambu kazibuthe eqine kakhulu, ikhulisa amandla ngo-30% -50% uma iqhathaniswa nozibuthe abayisicaba, okubenza balungele ukusetshenziswa kwamandla aphezulu.

● Umklamo Olungiselelwe: Ama-grooves angabhangqwa ne-multi-pole magnetization ukuze kuncishiswe ukuvuza kazibuthe, nakuba edinga ukucutshungulwa kwemishini eyinkimbinkimbi nokucatshangelwa kwezindleko ukuze kulinganiswe ukusebenza nokuqina.

Ungayikhetha Kanjani Ingubo Efanele Yomazibuthe Esiteshi?

● I-Nickel:Ukuzikhethela okujwayelekile, ukugqwala nokumelana nokugqoka, ukubukeka kwesiliva okukhanyayo, ukunamathela kokubola

● I-Epoxy:Okumnyama noma okumpunga, kufanelekile endaweni emanzi/amakhemikhali

● Zinc:izindleko eziphansi, kodwa hhayi njengokumelana nokugqwala njenge-nickel

● Igolide / i-Chrome:Ingasetshenziselwa amadivaysi ezokwelapha noma izingxenye zokuhlobisa eziphezulu

Izincomo Zokusetshenziswa Kwezindawo Ezihlukene Zomazibuthe Besiteshi

●Indawo Yasendlini (Izinga Lokushisa Elizinzile/Ukuswakama)

Ukwelashwa Okunconyiwe: I-Nickel Plating (Ni-Cu-Ni)

Izinzuzo: Imali engabizi kakhulu, isiphetho esicwebezelayo, ivimbela i-oxidation. Ilungele izinto zikagesi nezinembayo.

●Indawo yangaphandle/Yokuswakama Okuphezulu (Imvula, Umswakama)

Ukwelashwa Okunconyiwe: I-Epoxy Resin Coating (Mnyama/Mpunga)

Izinzuzo: Ukumelana okuhle kakhulu nokugqwala, imelana nokufuthwa ngosawoti. Ifanele imishini yasolwandle kanye nezinzwa zangaphandle.

●Izimo Zezinga Lokushisa Eziphezulu (80°C+)

Ukwelashwa okunconyiwe: I-Phosphating + I-High-Temp Epoxy Coating

Izinzuzo: Imelana nokushisa (150-200°C), ivimbela i-oxidation eshisayo. Isetshenziswa kuma-motor nasezintweni zezimoto.

●I-Acid Eqinile/i-Alkali noma Indawo Eyonakele Ngamakhemikhali

Ukwelashwa Okunconyiwe: Isembozo se-PTFE (Teflon)

Izinzuzo: Ayimelani namakhemikhali, ivikela ngogesi. Ilungele imishini yezokwelapha neyamakhemikhali.

Ungayikhetha Kanjani Usayizi We-Channel Magnet, Ibanga Le-Magnetic kanye Nesiqondiso Se-Magnetic Ngokusho Kwezidingo Zohlelo Lokusebenza?

Nquma Usayizi Ngokusekelwe Emkhathini Nezimfuneko Zamandla

Okokuqala fanisa indawo yokufaka (isb, usayizi wesikhala semoto), bese ulungisa ukujiya ngokuya ngezidingo zamandla kazibuthe:

- Izikhala ezincane: Sebenzisa amamodeli azacile (1.5–5mm)

- Amandla anamandla okudingekayo:Khetha izinguqulo ezijiyile (5–30mm)

Khetha Ibanga Le-Magnetic by Application Scenario

-Ukusetshenziswa okuvamile:(isb., abanikazi bezibuthe basendlini): N35–N42 (eyongayo)

- Izimboni/amandla aphezulu:(isb., izinjini, izisetshenziswa zezokwelapha): N45–N52 (amandla amelana nokushisa/aqinile)

- Izindawo ezinokushisa okuphezulu:Khetha "H/SH" amamodeli wesijobelelo (isb, N38SH)

Khetha Isiqondiso Sokugqama Ngokusekelwe Ohlotsheni Lokunyakaza

- I-adsorption emile:I-Axial magnetization (amandla ohlangothini olulodwa)

- Imishini ejikelezayo:I-Radial magnetization (isb., ama-motor rotor)

- Ukulawula ukunemba:I-Multi-pole magnetization (yehlisa ukulahleka kwamanje kwe-eddy)

Umthetho osheshayo:Usayizi ngesikhala, ibanga ngesimo, isiqondiso ngokunyakaza.

Amasu Okusebenzisa Ozibuthe Besiteshi Se-Neodymium Kumazinga Okushisa Aphezulu Nezimo Ezikhethekile Zokusebenza

Isimanga

Amazinga okushisa aphezulu aphazamisa ukuqondana kwezizinda kazibuthe, okubangela ukuphelelwa amandla kazibuthe ngokuphelele uma izinga lokushisa le-Curie leqiwe, kanye nokwehla kokusebenza ngisho nangaphansi kwalo.

I-Factor Enomthelelas

- Ukumelana nokushisa okubalulekile (isb, i-NdFeB inokubekezelelana okuphansi, i-SmCo inokubekezelelana okuphezulu).

- Ukushintshashintsha kwezinga lokushisa kusheshisa ukuguga.

Ukuvimbela

- Sebenzisa izinto ezimelana nokushisa okuphezulu (isib. i-SmCo).

- Thuthukisa ukunqanyulwa kokushisa (amasinki okushisa/amafeni okupholisa).

- Gwema ukushisa ngokweqile ngesikhathi sokusebenza.

Indlela Ejwayelekile Yokuhlola I-Pull Force kanye Nokucatshangelwa Okubalulekile

Indlela Yokuhlola

Sebenzisa isihloli se-tensile esilinganisiwe esine-non-magnetic fixture.

Khulisa kancane amandla okudonsa aqondile kuze kube yilapho uzibuthe uphuma endaweni yokuhlola.

Rekhoda inani lamandla aphezulu njengamandla okudonsa (N noma kgf).

Izici Ezibucayi

Isimo esingaphezulu: Okubalulekile kwepuleti lokuhlola/ukuphela kwendawo kufanele kufane nezicaciso zohlelo lokusebenza (isb, insimbi D36, Ra≤1.6μm).

Indawo yokuxhumana: Qinisekisa ukuthintana okugcwele nezikhala zomoya eziyiziro.

Isivinini sokuhlukanisa: Gcina izinga lokudonsa elingaguquki elingu-5-10 mm/s.

Izinyathelo zokuzivikela

Yenza izivivinyo eziphindaphindiwe ezingu-3-5 zokulinganisa.

Khipha uzibuthe amapuleti okuhlola phakathi kwezilingo uma uhlola omazibuthe abaningi.

Idokhumenti yezinga lokushisa elizungezile (lithinta ukusebenza kukazibuthe we-NdFeB).

Umhlahlandlela Wokwenza Ngokwezifiso – Indlela Yokuxhumana Ngokuphumelelayo Nabahlinzeki

● Umdwebo wobukhulu noma ukucaciswa (okuneyunithi ye-Dimensional)

● Izidingo zebanga lezinto (isb. i-N42 / N52)

● Incazelo yesikhombisi-ndlela sikaMazibuthe (isb. i-Axial)

● Okuthandwayo kokwelashwa okungaphezulu

● Indlela yokupakisha (inqwaba, igwebu, amabhamuza, njll.)

● Isimo sohlelo lokusebenza (ukusisiza sincome isakhiwo esingcono kakhulu)