Custom Rare Earth Magnets | Neodymium Magnets Manufacturer Factory

As a leading manufacturer of high-performance magnets, we specialize in creating custom rare earth magnets made from premium materials such as neodymium (NdFeB). These magnets are designed to provide powerful magnetic strength, precision, and durability, making them ideal for various industrial and commercial applications.

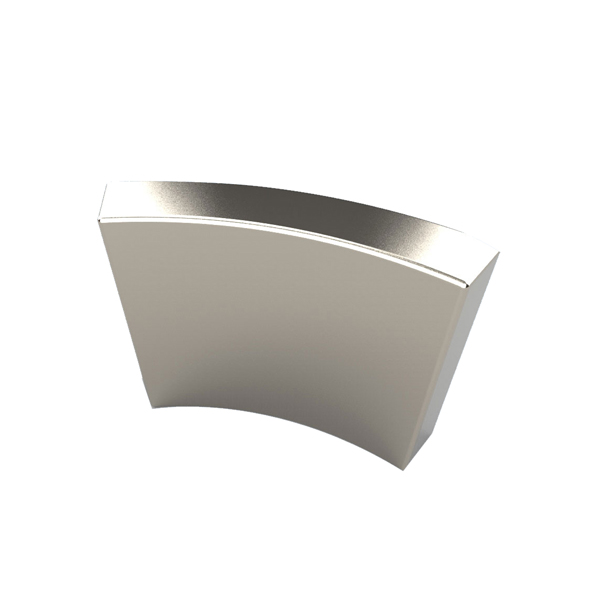

We specialize in manufacturing custom rare earth magnets made from high-quality neodymium (NdFeB) and other rare earth materials. Known for their powerful magnetic strength and durability, our custom magnets are designed to meet your exact specifications, including size, shape, and coating.

Custom Rare Earth Magnets Supplier

We are a leading custom rare earth magnets supplier, specializing in high-performance neodymium (NdFeB) magnets tailored to meet your exact specifications. Our magnets offer exceptional magnetic strength, durability, and precision, making them ideal for industries such as electronics, motors, sensors, and automotive systems. Whether you need bespoke sizes, shapes, or coatings, we provide reliable, high-quality solutions designed for a wide range of applications.

Choose Your Custom Rare Earth Magnets

- Our custom rare earth magnets, particularly those made from neodymium, offer exceptional magnetic force relative to their size. This makes them ideal for applications that require high magnetic energy in a compact form.

- We understand that each application has unique requirements. Whether you need specific shapes, sizes, coatings, or tolerances, we can customize the magnet to meet your exact needs. From small prototypes to large-scale production, we provide tailored solutions to ensure a perfect fit for your application

- Our magnets are built to last. With high resistance to demagnetization and environmental factors like heat, moisture, and corrosion, our rare earth magnets maintain their strength and reliability over time, even in the most demanding conditions.

Strong Custom Magnet

Custom Neodymium Magnet

Rare Earth Custom Magnet

Custom NdFeB Magnets

Custom Strong Magnets

Couldn’t find what you looking for?

Generally, there are stocks of common neodymium magnets or raw materials in our warehouse. But if you have special demand, we also provide customization service. We also accept OEM/ODM.

Our Customised Services

We offer a full range of customization options for neodymium magnets to meet your specific needs. Whether you require a unique color coating, precise size specifications, tailored design for magnetic strength and polarity, or a specialized shape such as disks, blocks, or rings, we can accommodate. Our materials can be customized to ensure the magnet's properties match your application requirements, and we provide surface treatments like nickel, zinc, and epoxy for added durability and corrosion resistance.

Choose from a variety of colors for magnet coatings to match product aesthetics or functional requirements. Popular options include nickel, zinc,gold, black epoxy, and more. Custom colors are available upon request to suit branding or application-specific needs.

We can manufacture magnets in virtually any size, from tiny magnets for electronics to larger sizes for industrial applications. Custom dimensions allow precise fit and functionality, ensuring each magnet meets your specific requirements.

We work closely with clients to create unique designs, including custom shapes, magnetic strength, and polarity arrangements. This flexibility enables us to support specialized uses across industries such as automotive, electronics, and medical.

Available in a range of shapes, including disk, block, ring, and countersunk, as well as fully customized shapes to meet unique application requirements. Custom shapes improve integration into final products for seamless performance.

Although our commonly used magnet is N52, we can use different magnet grade according to the magnetic properties, strength and temperature resistance.

Our magnets can be coated with materials like nickel, zinc, epoxy, or gold to enhance durability, corrosion resistance, and visual appeal. We recommend coatings based on application needs, environment, and required lifespan.

We offer flexible packaging solutions, from bulk options to individual packaging for retail-ready products. Custom packaging options, including eco-friendly materials and protective packaging, ensure magnets arrive in optimal condition.

Add a logo or branding to the magnets or packaging to enhance brand recognition. Laser engraving and other branding methods are available, allowing magnets to serve as promotional tools or to reflect corporate identity.

Fullzen Neodymium Magnet Application

Neodymium magnets, valued for their strength and compact size, are essential across industries. In electronics, they improve sound and device functions, while in motors and generators, they enable efficient designs for electric vehicles and wind turbines. They’re also vital in medical equipment like MRI machines, automotive systems for safety and performance, and renewable energy technology. Their powerful, versatile applications make them a key component in modern technology and industry.

Neodymium Magnets Process

- Raw Material Mixing: Neodymium, iron, and boron are mixed with minor elements to optimize properties.

- Melting and Casting: The mixture is melted, cast into molds, and cooled into alloy blocks.

- Powdering: The blocks are crushed into fine powder.

- Pressing and Aligning: The powder is pressed in a magnetic field to align the particles.

- Sintering: The pressed powder is heated to fuse particles, forming solid magnets.

- Shaping: Magnets are cut and shaped as needed.

- Coating: A protective layer, like nickel or epoxy, is applied to prevent corrosion.

- Magnetization: Magnets are exposed to a strong magnetic field to activate their magnetic properties.

- Quality Control: Each magnet is tested for strength, precision, and coating quality.

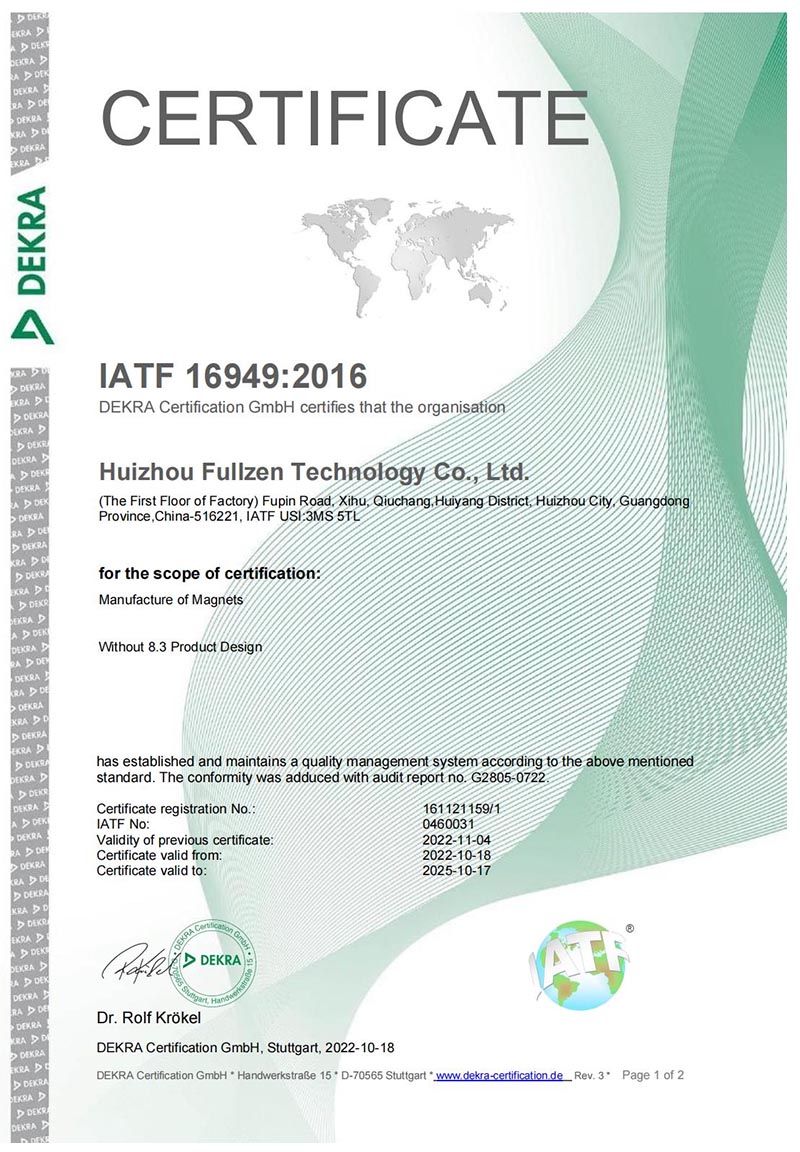

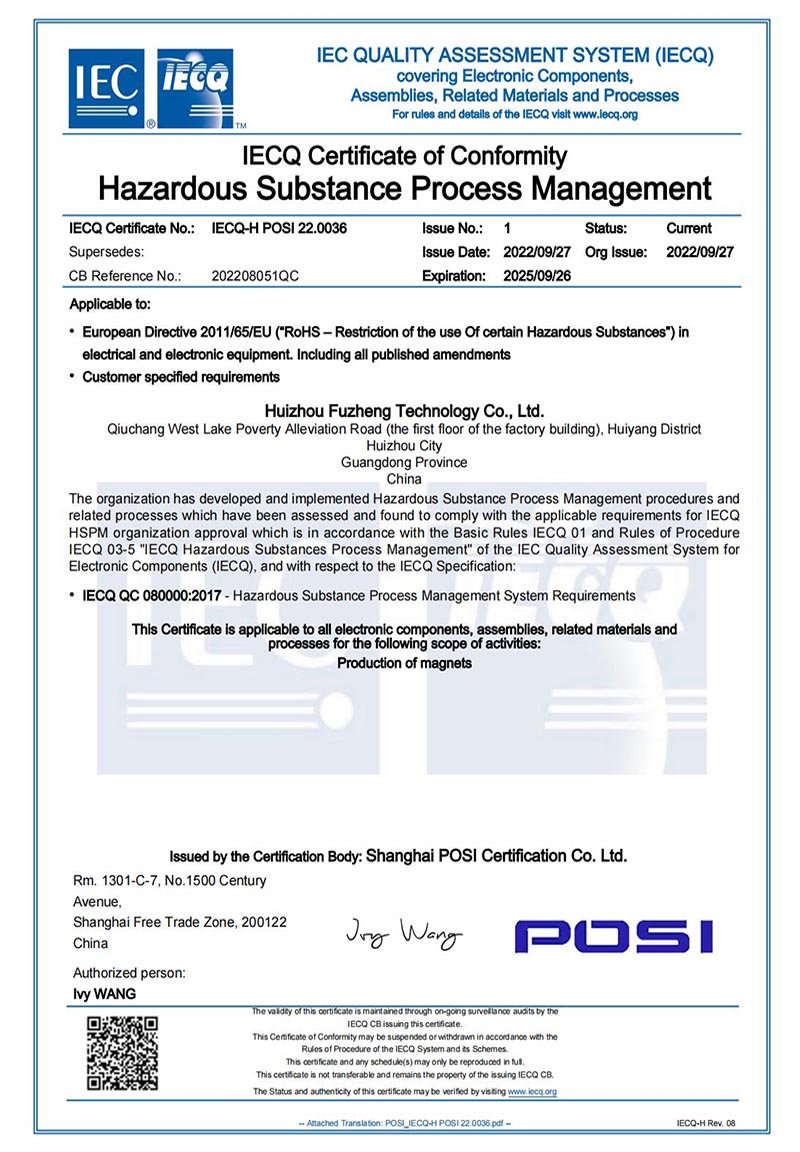

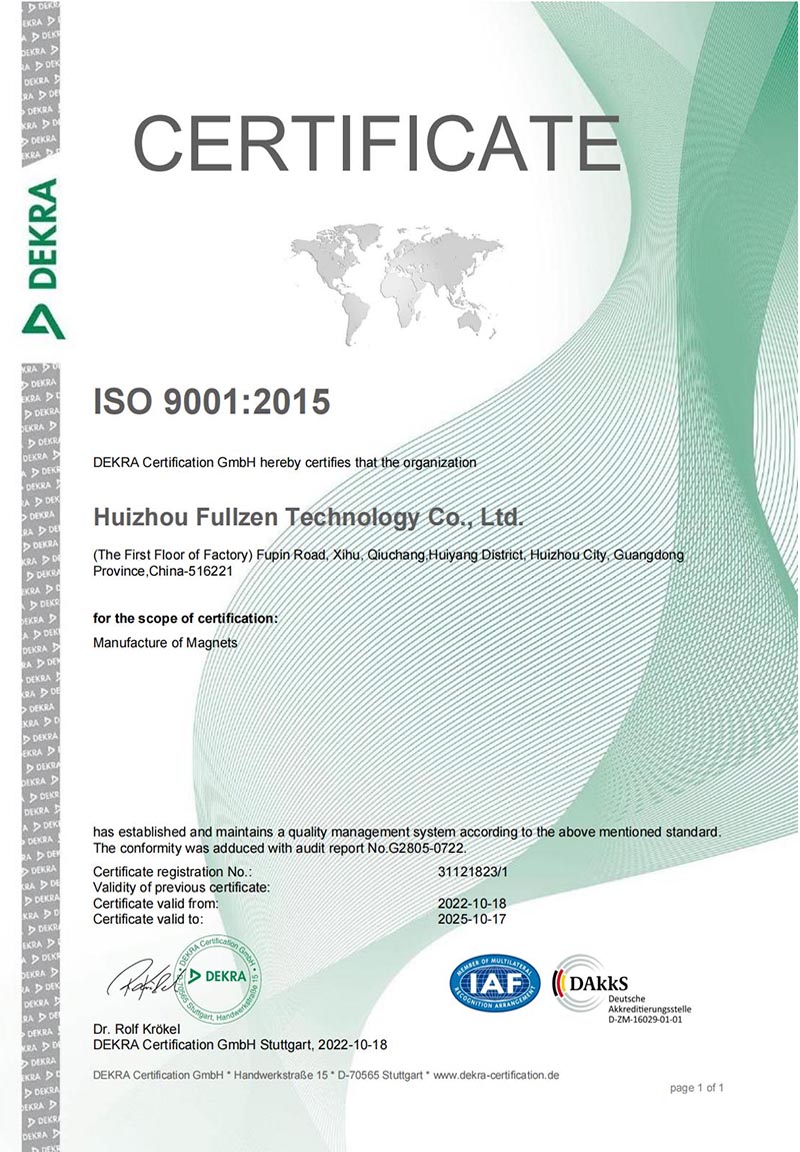

Certificates

Since its establishment, our company has successfully obtained eight major system certifications, including certifications in the medical and automotive industries, as well as social responsibility accreditation. These certifications underscore our commitment to maintaining the highest standards of quality, safety, and ethical responsibility across diverse industries. Our dedication to rigorous standards not only reflects our capability to meet industry-specific requirements but also demonstrates our responsibility towards our clients, partners, and society. Through these achievements, we continue to build a foundation of trust, offering reliable products and services that exceed expectations and uphold the values of professionalism and integrity.

IATF16949

IECQ

ISO9001

ISO13485

ISO14001

ISO45001

ISOIEC27001

SA8000

FAQs

1. What are custom rare earth magnets made of?

Custom rare earth magnets are typically made from high-performance materials like neodymium (NdFeB) or samarium-cobalt (SmCo). These materials are known for their high magnetic strength and ability to maintain magnetic properties under harsh conditions.

2. How do I know which type of custom rare earth magnet I need?

The type of magnet you need depends on factors such as the required magnetic strength, operating temperature, size, and environmental conditions. Neodymium magnets are best for applications requiring maximum strength, while samarium-cobalt magnets are ideal for high-temperature environments. Consult with our engineers for tailored recommendations based on your specific application.

3. What are the benefits of custom rare earth magnets over standard magnets?

Custom rare earth magnets offer superior magnetic strength and can be tailored to specific shapes, sizes, and coatings, making them ideal for unique or specialized applications. Their durability and resistance to demagnetization also make them more reliable over time compared to standard magnets.

4. Can you customize the size and shape of rare earth magnets?

Yes, we specialize in producing custom rare earth magnets in a wide range of sizes and shapes. Whether you need discs, blocks, rings, cylinders, or any other custom configuration, we can tailor the magnets to fit your exact requirements.

5. What industries use custom rare earth magnets?

Custom rare earth magnets are used in a variety of industries, including electronics, automotive, medical devices, robotics, renewable energy, and aerospace. They are ideal for applications such as motors, sensors, magnetic assemblies, actuators, and more.

6. How strong are custom rare earth magnets?

Custom rare earth magnets, especially those made from neodymium (NdFeB), are the strongest permanent magnets available. Their strength is measured in Mega Gauss Oersteds (MGOe), and they can generate a very high magnetic force even in small sizes, providing superior performance compared to other magnet types.

7. What coatings are available for custom rare earth magnets?

Custom rare earth magnets can be coated with various materials such as nickel, zinc, epoxy, gold, and chrome. These coatings help prevent corrosion and ensure longevity, particularly in harsh or outdoor environments.

8. What is the minimum order quantity (MOQ) for custom rare earth magnets?

The minimum order quantity (MOQ) for custom rare earth magnets typically depends on the size and complexity of the design. However, we can accommodate both small prototypes and large-scale production orders. Please contact us for specific MOQ details based on your needs.

9. How long does it take to produce custom rare earth magnets?

The production timeline for custom rare earth magnets varies depending on the complexity of the order and the quantity. Typically, lead times range from 2 to 4 weeks for small batches, with larger orders requiring additional time for production and testing. We always strive to deliver within agreed timelines.

10. Are custom rare earth magnets safe to handle?

Custom rare earth magnets, particularly neodymium magnets, are strong and can be dangerous if mishandled. They can cause injury if pinched between fingers or if two magnets snap together. Proper handling, storage, and use of safety precautions are essential. We recommend consulting the safety guidelines provided with each order.