Custom Neodymium Magnets

Custom neodymium magnets according to your company requirements. We sell all grades of neodymium magnets, custom shapes, sizes and coating

Neodymium Magnets Manufacturer,factory In China

Huizhou Fullzen Technology Co.,Ltd is a professional neodymium magnet manufacturer, custom magnet manufacturer,factory, and supplier in china since 2016. We are specialized in experiment, design, engineering, manufacturing, inspection, and assembling of custom neodymium magnets. Customization to meet your company requirements. We offer off-the-shelf products as well as customized services,custom design of permanent magnets,custom shaped neodymium magnets, tailor-made for your industry.

Choose Your Neodymium Magnets

Neodymium magnet video

Neodymium magnets introduction

Neodymium magnet, also known as NdFeB magnet, is a Tetragonal crystal system crystal formed by Nd2Fe14B. It is a magnetic material made from metal praseodymium neodymium through preparation and sintering. This kind of magnet is a permanent magnet whose magnetism is second only to Absolute zero holmium magnet, and it is also the most commonly used Rare-earth magnet.

Neodymium magnets chemical composition

Neodymium iron boron permanent magnet material is a permanent magnet material based on the intermetallic compound Nd2Fe14B. The main components are rare earth elements neodymium (Nd), iron (Fe), and boron (B). The main rare earth element is neodymium (Nd), which can be partially replaced by other rare earth metals such as dysprosium (Dy) and praseodymium (Pr) to obtain different properties. Iron can also be partially replaced by other metals such as cobalt (Co) and aluminum (Al). The boron content is small, but it plays an important role in the formation of tetragonal crystal structure intermetallic compounds, making the compounds have high saturation magnetization, high uniaxial anisotropy, and high Curie temperature.

Neodymium magnets Process flow

Process flow: batching → melting and ingot making/strip throwing → powder making → molding → sintering and tempering → magnetic testing → grinding processing → pin cutting processing → electroplating → finished product. The ingredients are the foundation, and sintering and tempering are the key.

Production tools and performance testing tools for neodymium iron boron magnet blanks: including melting furnace, strip throwing furnace, crushing machine, airflow mill, compression molding machine, vacuum packaging machine, isostatic press machine, sintering furnace, heat treatment vacuum furnace, magnetic performance tester, Gaussian meter.

Neodymium iron boron magnet machining tools: centerless grinding, rounding machine, double end grinding, flat grinding, slicing machine, double-sided grinding, wire cutting, bench drill, irregular grinding, etc.

Neodymium magnets applications

Sintered neodymium iron boron permanent magnet materials have excellent magnetic properties and are widely used in fields such as electronics, power machinery, medical equipment, toys, packaging, hardware machinery, aerospace, etc. Common ones include permanent magnet motors, speakers, magnetic separators, computer disk drives, magnetic resonance imaging equipment instruments, etc.

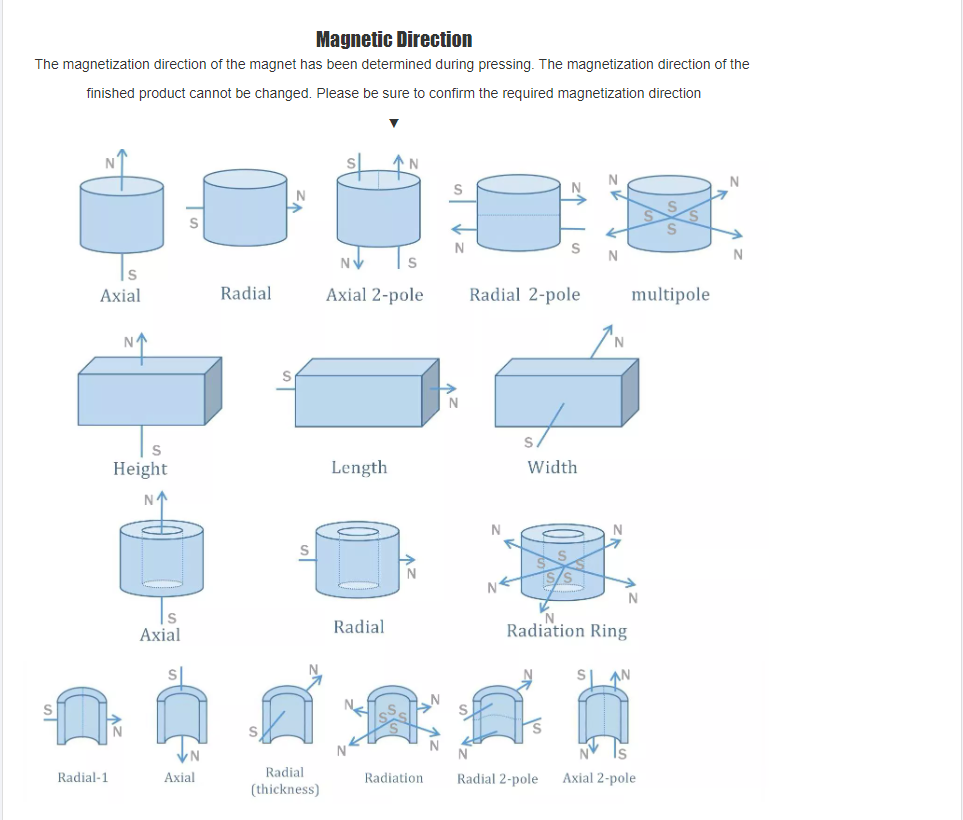

Neodymium magnets magnetization direction and surface coating

Couldn’t find what you looking for?

Generally, there are stocks of common neodymium magnets or raw materials in our warehouse. But if you have special demand, we also provide customization service. We also accept OEM/ODM.

Custom Neodymium Magnets

Huizhou Fullzen Technology Co.,Ltd is a professional magnet manufacturer.Our company custom rare earth magnets and one of the top custom magnet manufacturers.We are specialized in experiment, design, engineering, manufacturing, inspection and assembling of custom neodymium magnets. Customization to meet your company requirements.As the following custom guide shows, we sell complete neodymium magnets. We offer off-the-shelf products as well as customized services, custom permanent magnet,tailor-made for your industry.Such as large neodymium arc magnets customized for you.

Size and shape:

We can provide customized disc, cylinder, ring, square cube, rectangular block, arc, countersunk, hook and other irregular permanent magnets.

Manufacture:

We use automatation equipments to cut and grind the raw materials to make the dimantions of the permanent magnet you want, with micro tolerance, to achieve the finishing effect.

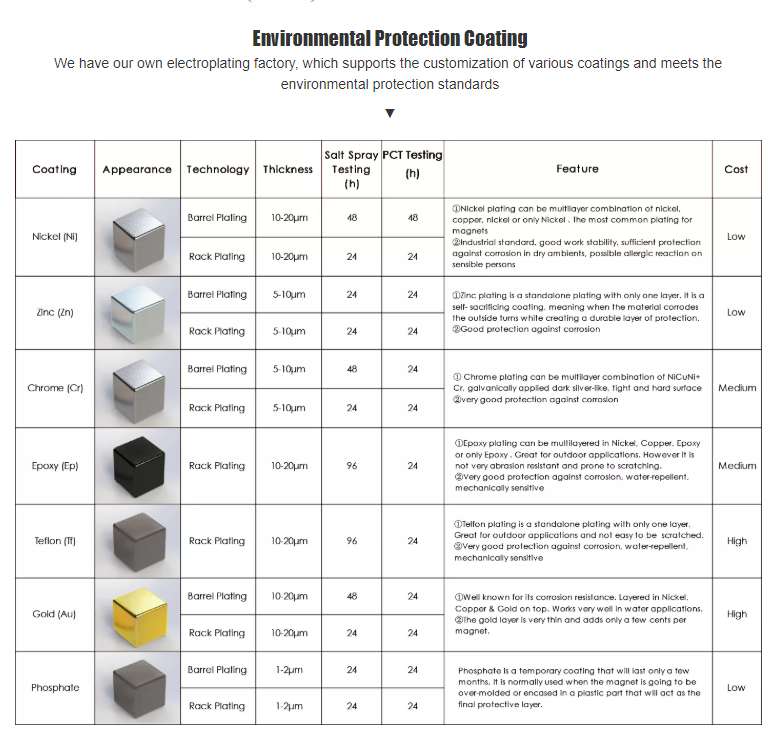

Surface treatment:

Permanent magnets are easy to be oxidized. According to customer needs, the surface will be coated, epoxy coated or electroplated to prevent corrosion. We can provide nickel plating, galvanization, electrophoresis and other services.

Temperature Notes:

Permanent magnet is temperature sensitive. We will strictly produce according to the customer's demand for permanent magnets with high temperature resistance.

Custom guide

| Material | Sintered Neodymium-Iron-Boron ( NdFeB ) | |

| Size | Custom | |

| Shape | Block, Disc, Cylinder, Bar, Ring, Countersunk, Segment Hook, Cup, Trapezoid, Irregular shapes,etc. | |

| Performance | N33 N35 N38 N40 N42 N45 N48 N50 N52 N54 etc. | |

| Coating | Zn, Ni-Cu-Ni, Ni, Gold, Silver, Copper, Epoxy, Chrome, etc | |

| Size tolerance | ±0.05mm for diamater /thickness, ±0.1mm for width/ length | |

| Magnetization | Thickness Magnetized, Axially Magnetized, Diametrally Magnetized, Multi-poles magnetized, Radial Magnetized. (Customzied specific requirements magnetized) | |

| Max. Working Temperature | Grade | Max. Operating Temperature |

| N35-N52 | 80°C (176°F) | |

| 33M- 48M | 100°C (212°F) | |

| 33H-48H | 120°C (248°F) | |

| 30SH-45SH | 150°C (302°F) | |

| 30UH-40UH | 180°C (356°F) | |

| 28EH-38EH | 200°C (392°F) | |

| 28AH-35AH | 220°C (428°F) | |

MOQ & Lead Time

| Pieces | Lead Time |

| 1000-10000 | 10 days |

| 10000-100000 | 20 days |

| 100000-1000000 | 30 days |

What we can offer you…

We are professional Neodymium Magnet manufacturer and supplier in China. We can produce Neodymium Magnet (NdFeB magnet) according to your requirements.

Magnet performance

There are mainly the following three performance parameters to determine the performance of the magnet:

Remanence Br: After the permanent magnet is magnetized to technical saturation and the external magnetic field is removed, the retained Br is called the residual magnetic induction.

Coercive force Hc: To reduce the B of the permanent magnet magnetized to technical saturation to zero, the required reverse magnetic field strength is called the magnetic induction coercive force, abbreviated as coercive force.

Magnetic energy product BH: It represents the magnetic energy density established by the magnet in the air gap space (the space between the two magnetic poles of the magnet), that is, the static magnetostatic energy per unit volume of the air gap. Since this energy is equal to the product of the magnet's Bm and Hm, it is called the magnetic energy product.

We can customize permanent magnets with properties between N35-N54 on the market.

Parameter of Magnets

| Grade | Remanence | Coercive Force | Intrinsic Coercive Force | Maximum Energy Product | Working Temp | ||||

| Br | Hcb | Hcj | BH max | Tw | |||||

| mT | KGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | ||

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 80℃ |

| N40 | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 302-326 | 38-41 | 80℃ |

| N42 | 1280-1320 | 12.8-13.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 318-342 | 40-43 | 80℃ |

| N45 | 1320-1370 | 13.2-13.7 | ≥876 | ≥11.0 | ≥955 | ≥12 | 342-366 | 43-46 | 80℃ |

| N48 | 1370-1420 | 13.7-14.2 | ≥892 | ≥11.2 | ≥955 | ≥12 | 366-390 | 46-49 | 80℃ |

| N50 | 1390-1440 | 13.9-14.4 | ≥836 | ≥10.5 | ≥955 | ≥12 | 374-406 | 47-51 | 80℃ |

| N52 | 1420-1470 | 14.2-14.7 | ≥836 | ≥10.5 | ≥876 | ≥11 | 390-422 | 49-53 | 80℃ |

| N55 | 1460-1520 | 14.6-15.2 | ≥716 | ≥9 | ≥876 | ≥11 | 414-446 | 52-56 | 80℃ |

| 35M | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100℃ |

| 38M | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 100℃ |

| 40M | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 100℃ |

| 42M | 1280-1320 | 12.8-13.2 | ≥995 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 100℃ |

| 45M | 1320-1370 | 13.2-13.7 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 100℃ |

| 48M | 1360-1420 | 13.6-14.2 | ≥1019 | ≥12.8 | ≥1114 | ≥14 | 366-390 | 46-49 | 100℃ |

| 50M | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | 100℃ |

| 52M | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1035 | ≥13 | 390-422 | 49-53 | 100℃ |

| 33H | 1130-1170 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-271 | 31-34 | 120℃ |

| 35H | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120℃ |

| 38H | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 120℃ |

| 40H | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 120℃ |

| 42H | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 120℃ |

| 45H | 1320-1370 | 13.2-13.7 | ≥971 | ≥12.2 | ≥1353 | ≥17 | 342-366 | 43-46 | 120℃ |

| 48H | 1360-1420 | 13.6-14.2 | ≥1027 | ≥12.9 | ≥1353 | ≥17 | 366-390 | 46-49 | 120℃ |

| 50H | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 374-406 | 47-51 | 120℃ |

| 52H | 1420-1470 | 14.2-14.7 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 390-422 | 49-53 | 120℃ |

| 28SH | 1040-1090 | 10.4-10.9 | ≥780 | ≥9.8 | ≥1592 | ≥20 | 207-231 | 25-28 | 150℃ |

| 30SH | 1080-1130 | 11.3-11.7 | ≥804 | ≥10.1 | ≥1592 | ≥20 | 223-247 | 28-31 | 150℃ |

| 33SH | 1130-1170 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 | 150℃ |

| 35SH | 1170-1220 | 11.7-12.2 | ≥876 | ≥11 | ≥1592 | ≥20 | 263-287 | 33-36 | 150℃ |

| 38SH | 1220-1250 | 12.2-12.5 | ≥907 | ≥10.5 | ≥1592 | ≥20 | 287-310 | 36-39 | 150℃ |

| 40SH | 1250-1280 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 150℃ |

| 42SH | 1280-1320 | 12.8-13.2 | ≥971 | ≥12.2 | ≥1592 | ≥20 | 318-342 | 40-43 | 150℃ |

| 45SH | 1320-1370 | 13.2-13.7 | ≥979 | ≥12.3 | ≥1592 | ≥20 | 342-366 | 43-46 | 150℃ |

| 50SH | 1390-1440 | 13.9-14.4 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 374-406 | 47-51 | 150℃ |

| 52SH | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 390-422 | 49-53 | 150℃ |

| 28UH | 1020-1080 | 10.2-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 25-28 | 180℃ |

| 33UH | 1130-1170 | 11.3-11.7 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 247-271 | 31-34 | 180℃ |

| 35UH | 1170-1220 | 11.7-12.2 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 263-287 | 33-36 | 180℃ |

| 38UH | 1220-1250 | 12.2-12.5 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 287-310 | 36-39 | 180℃ |

| 40UH | 1250-1280 | 12.5-12.8 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 302-326 | 38-41 | 180℃ |

| 42UH | 1270-1320 | 12.7-13.2 | ≥971 | ≥12.2 | ≥1990 | ≥25 | 310-342 | 39-43 | 180℃ |

| 50UH | 1390-1440 | 13.9-14.4 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 374-406 | 47-51 | 180℃ |

| 52UH | 1420-1470 | 14.2-14.7 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 390-422 | 49-53 | 180℃ |

| 28EH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 25-28 | 200℃ |

| 30EH | 1080-1130 | 11.3-11.7 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | 200℃ |

| 33EH | 1130-1170 | 11.3-11.7 | ≥820 | ≥10.3 | ≥2388 | ≥30 | 247-271 | 31-34 | 200℃ |

| 35EH | 1170-1220 | 11.7-12.2 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 263-287 | 33-36 | 200℃ |

| 28AH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2706 | ≥34 | 207-231 | 25-28 | 230℃ |

| 30AH | 1070-1130 | 10.7-11.3 | ≥812 | ≥10.2 | ≥2706 | ≥34 | 215-247 | 27-31 | 230℃ |

| 33AH | 1110-1170 | 11.1-11.7 | ≥820 | ≥10.3 | ≥2706 | ≥34 | 239-271 | 30-34 | 230℃ |

Packaging details