Neodymium Magnet with Handle – Direct Manufacturer in China for Wholesale & Custom Solutions

Fullzen is a professional Neodymium Magnet with Handle manufacturer in China, specializing in high-strength magnets for industrial clamping, mold fixation, metal adsorption, and other applications. We offer a variety of pull-out strength specifications, handle material options, and OEM customization services, supporting bulk purchases and fast delivery.

Our Neodymium Magnet with Handle Samples

We provide a variety of neodymium magnet with handle in different sizes, grades (N35–N52), and coatings. You can request a free sample to test magnetic strength and fit before placing bulk orders.

Flat Neodymium Magnet with Handle

Fishing Magnet

Lifting Magnet

N52 U shape neodymium magnet

Request a Free Sample – Test Our Quality Before Bulk Order

Custom Neodymium Magnet with Handle – Process Guide

Our production process is as follows: After the customer provides drawings or specific requirements, our engineering team will review and confirm them. After confirmation, we will make samples to ensure that all products meet the standards. After the sample is confirmed, we will carry out mass production, and then pack and ship to ensure efficient delivery and quality assurance.

Our MOQ is 100pcs,We can meet customers' small batch production and large batch production. The normal proofing time is 7-15 days. If there is magnet stock, the proofing can be completed. within 3-5 days. The normal production time of bulk orders is 15-20 days. If there is magnet inventory and forecast orders, the delivery time can be advanced to about 7-15 days.

Applications of Neodymium Magnet with Handle

Customization Options

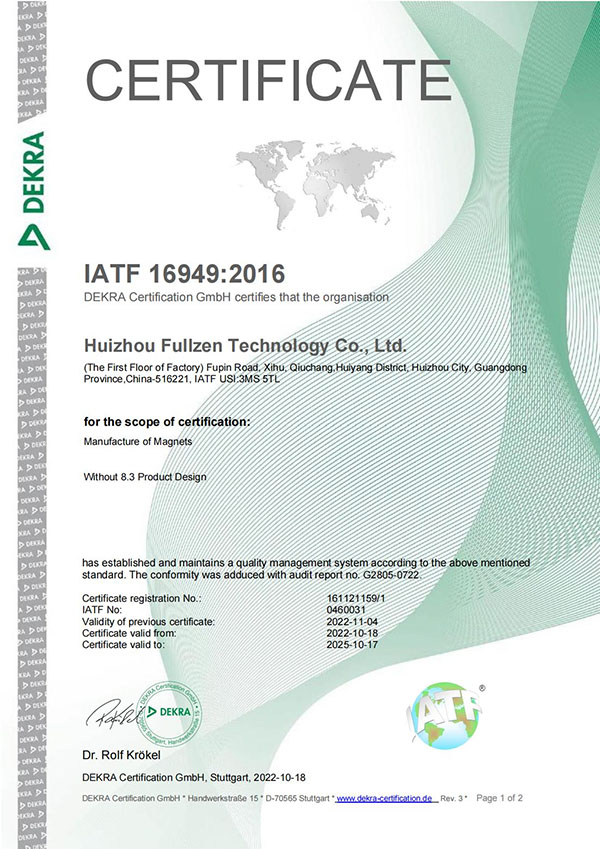

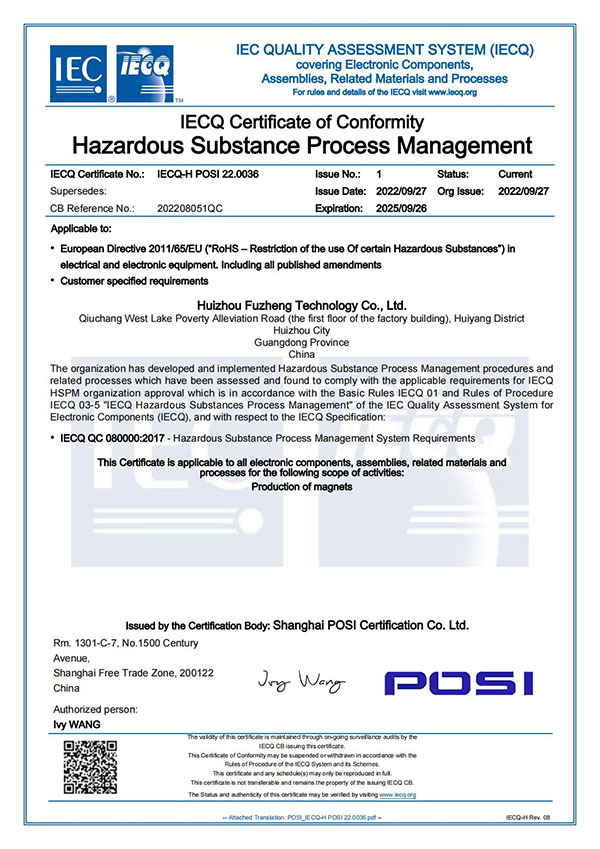

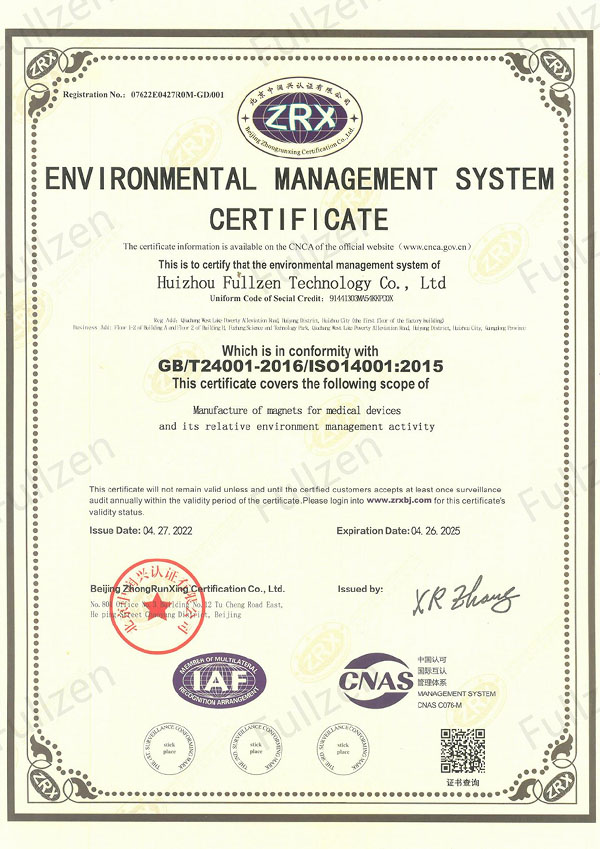

Quality Assurance & Certifications

Why Choose Us as Your Neodymium Magnet with Handle Manufacturer?

As a Magnet manufacturer factory, we have our own Factory based in China,and we can provide you OEM/ODM services.

High-performance neodymium material: N35–N52 optional, supports high temperature and anti-corrosion coating (nickel plating, epoxy, etc.).

Customization flexibility: size/coating/magnetizing direction/logo can all be customized.

Rich export experience: large batch quantities exported to Europe, America, Japan, South Korea,Pakistan,the Middle East, etc.

IATF16949

IECQ

ISO9001

ISO13485

ISOIEC27001

SA8000

Full Solutions From Neodymium Magnet Manufacturer

Fullzen Technology is ready to help you with your project by developing and manufacturing Neodymium Magnet. Our assistance can help you complete your project on time and within budget. We have several solutions to help you succeed.

Supplier Management

Our excellent supplier management and supply chain control management can help our clients to obtain a quick and accurate delivery of quality products.

Production Management

Every aspect of production is handled under our supervision for uniform quality.

Strict Quality Management And Testing

We have a well-trained and professional (Quality Control) quality management team. They are trained to manage the processes of material procurement, finished product inspection, etc.

Custom Service

We do not only provide you with a high-quality magsafe rings but also offer you custom packaging and support.

Document Preparation

We will prepare the complete documents, such as bill of material, purchase order, production schedule, etc., according to your market requirements.

Approachable MOQ

We can meet most customers' MOQ requirements, and work with you to make your products unique.

Packaging details

Start Your OEM/ODM Journey

FAQs about Neodymium Magnet with Handle

1000pcs,we support sample before bulk order.

Normal Bulk orders delivery time is 15-20 days, but if you can provide a forecast plan before placing an order or if we have stock, the delivery date can be advanced.

NdFeB magnets are not as heat-resistant as Alnico magnets, which can withstand temperatures of 450 to 550 °C. NdFeB magnets generally withstand temperatures of around 80 to 220°C.

We can provide zinc coating, nickel coating, chemical nickel, black zinc and black nickel, epoxy, black epoxy, gold coating etc...

The magnetic field of each shape of magnet is different. We can customize the shape and magnetization direction to meet customer requirements.

It can be replaced before mass production is confirmed.

We support sample testing, salt spray testing and quality inspection.

Professional Knowledge & Buying Guide for Industrial Buyers

Neodymium Magnet with Handle Design Principles and Advantages

Mechanical Advantage (Easy to Remove):

The handle provides a long lever arm. When removing, simply flipping the handle generates a peeling force, easily breaking the magnetic attraction. This solves the core pain point of traditional strong magnets: "easy to attach, difficult to remove."

Safety Advantage (Anti-Pinching):

The handle keeps fingers and hands away from the strong magnetic field, fundamentally eliminating the risk of pinching when removing or placing the magnet or accidentally attaching metal.

Operational Convenience Advantage (Effortless, Efficient):

Effortless: No manual peeling required, making operation easy.

How to Choose the Right Coating for Neodymium Magnet with Handle?

● Nickel: General choice, rust and wear resistant, bright silver appearance,Corrosion resistant coating

● Epoxy: Black or gray, suitable for wet/chemical environments

● Zinc: low cost, but not as corrosion resistant as nickel

● Gold / Chrome: Can be used for medical devices or high-end decorative parts

Magnetization Direction: What Industrial Buyers Must Know?

● Axial: points from one arm to the other, suitable for clamping applications

● Diametrical: Less commonly used for U-shaped, but customizable

● Multi-pole: for special sensors/motors

If you can provide drawings or explain the purpose, we can help you determine the most suitable magnetization direction and solution.

How to choose the appropriate tensile strength specification?

For lightweight everyday use (cabinet doors, box lids): Choose a 10-25kg capacity. It opens and closes easily and prevents accidental popping.

For medium-sized equipment (cabinets, tool boxes): Choose a 25-50kg capacity. It has a secure grip and requires a slight two-handed opening.

For heavy-duty industrial use (electrical control cabinets, security doors): Choose a 50kg capacity or higher. It is sealed to prevent accidental opening and often requires specialized tools.

Key Notes:

The nominal pull force refers to the pull force applied to mild steel plates. The pull force applied to stainless steel and aluminum will be significantly reduced, and a conductive magnet must be attached.

Check the mechanical strength of the handle (screws, material); this determines the maximum safe pull force, not the magnetic strength itself.

What is Pull Force?

Pull force is the maximum force required to separate a magnet from a steel surface, usually measured in kilograms or pounds. This depends on several factors:

● Magnet material and grade (e.g., NdFeB N52 vs. Alnico 5)

● Condition of contacting surfaces (clean, flat, thick, uncoated steel = best)

● Direction of force (straight-line pull is ideal; sideways shear can significantly reduce holding force)

● Air gaps and coatings (even thin coatings or gaps can degrade performance)

Common mistakes in estimating pull force

● Assuming that pull force scales linearly with size.

● Larger neodymium magnet with handle may not produce correspondingly higher pull forces if the inter-pole gap or surface contact is not optimized.

Customization Guide – How to Communicate Efficiently with Suppliers

● Dimensional drawing or specification (with Dimensional unit)

● Material grade requirements (e.g. N42 / N52)

● Magnetization direction description (e.g. Axial)

● Surface treatment preference

● Packaging method (bulk, foam, blister, etc.)

● Application scenario (to help us recommend the best structure)