Neodymium Segment Magnets – China Direct Wholesale & Customization Manufacturer

As a leading China-based manufacturer of high-performance neodymium segment magnets, we specialize in custom curved and segmented magnet solutions for motors, generators, magnetic couplers, and precision industrial applications. Offering N35-N52 grades, multiple protective coatings, and tight tolerances, we help clients optimize performance while reducing supply chain costs.We have cooperative brands both at home and abroad and have a good reputation.

Our Neodymium Segment Magnets Samples

We provide a variety of neodymium segment magnets samples in different sizes, grades (N35–N52), and coatings. You can request a free sample to test magnetic strength and fit before placing bulk orders.Besides,all of our magnet prodcts such as disc magnet,U shape magnet,ring magnet could also provide sample,custom request could contact us.

CU- Neodymium Magnets Arc Segments

Zinc-Neodymium Magnets Arc Segment

Arc Segment Neodymium Magnet

N52 Neodymium Rare Earth Arc Segment Magnet

Segment Neodymium Magnet

NdFeB Arc Magnet with Nickel Coating

Neodymium Arc Magnets

Request a Free Sample – Test Our Quality Before Bulk Order

Custom Neodymium Segment Magnets – Process Guide

Our production process is as follows: After the customer provides drawings or specific requirements, our engineering team will review and confirm them. After confirmation, we will make samples to ensure that all products meet the standards. After the sample is confirmed, we will carry out mass production, and then pack and ship to ensure efficient delivery and quality assurance.

Our MOQ is 100pcs,We can meet customers' small batch production and large batch production. The normal proofing time is 7-15 days. If there is magnet stock, the proofing can be completed. within 3-5 days. The normal production time of bulk orders is 15-20 days. If there is magnet inventory and forecast orders, the delivery time can be advanced to about 7-15 days.

Applications of Neodymium Segment Magnets

Why Choose Us as Your Neodymium Segment Magnets Manufacturer?

As a Magnet manufacturer factory, we have our own Factory based in China,and we can provide you OEM/ODM services.

High-performance neodymium material: N35–N52 optional, supports high temperature and anti-corrosion coating (nickel plating, epoxy, etc.).

Customization flexibility: size/dimensional tolerance/coating/magnetizing direction/logo can all be customized.

Rich export experience: large batch quantities exported to Europe, America, Japan, South Korea,Pakistan,the Middle East, etc.

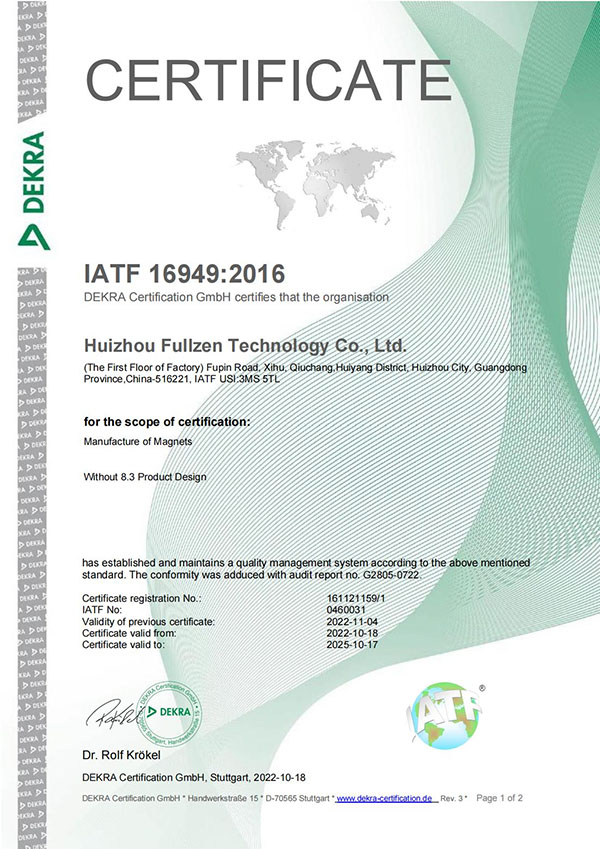

IATF16949

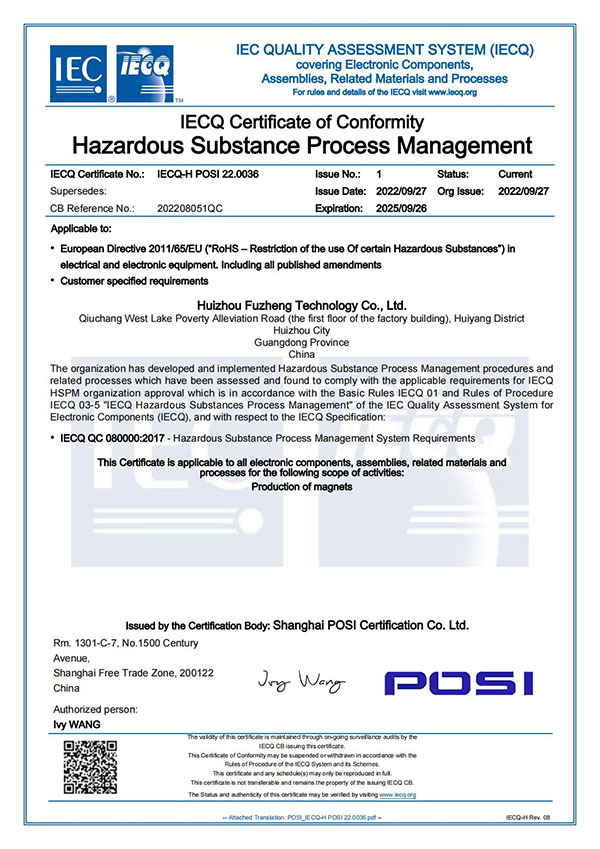

IECQ

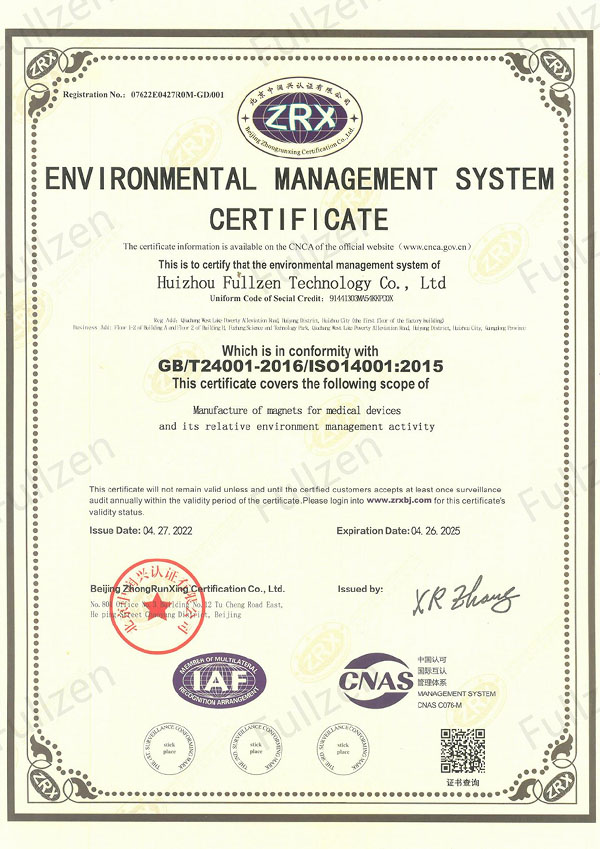

ISO9001

ISO13485

ISOIEC27001

SA8000

Full Solutions From Neodymium Magnet Manufacturer

Fullzen Technology is ready to help you with your project by developing and manufacturing Neodymium Magnet. Our assistance can help you complete your project on time and within budget. We have several solutions to help you succeed.

Supplier Management

Our excellent supplier management and supply chain control management can help our clients to obtain a quick and accurate delivery of quality products.

Production Management

Every aspect of production is handled under our supervision for uniform quality.

Strict Quality Management And Testing

We have a well-trained and professional (Quality Control) quality management team. They are trained to manage the processes of material procurement, finished product inspection, etc.

Custom Service

We do not only provide you with a high-quality magsafe rings but also offer you custom packaging and support.

Document Preparation

We will prepare the complete documents, such as bill of material, purchase order, production schedule, etc., according to your market requirements.

Approachable MOQ

We can meet most customers' MOQ requirements, and work with you to make your products unique.

Packaging details

Start Your OEM/ODM Journey

FAQs about Neodymium Segment Magnets

1000pcs.Before bulk order we support free sample.

Normal Bulk orders delivery time is 15-20 days, but if you can provide a forecast plan before placing an order or if we have stock, the delivery date can be advanced.

We have magnetization and quality inspection processes to ensure that each batch's quality falls within specified limits. Furthermore, we offer excellent after-sales service. If you have any questions, please contact us promptly.

We can provide zinc coating, nickel coating, chemical nickel, black zinc and black nickel, epoxy, black epoxy, gold coating etc...

The magnetic field of each shape of magnet is different. We can customize the shape and magnetization direction to meet customer requirements.

Brushless DC motors (BLDC): For drones, such as aerial photography, we recommend N50-N52 or N48H.

Electric vehicle drive motors: For main drive motors, we recommend 48SH or 45UH.

Industrial servo motors: For robot joints and precision machine tools, we recommend 40H or 42SH.

We support sample testing. If you have any questions, please contact us and we'll do our best to help you.

Professional Knowledge & Buying Guide for Industrial Buyers

What are the structural principles and magnetic advantages of neodymium segment magnets?

● Structural Principle: The arc-shaped design creates a closed or nearly closed circular magnetic circuit, allowing arc-shaped magnets to focus more effectively than other magnets.

● Magnetic Advantages: The magnetic field is strong and concentrated, with good uniformity and strong resistance to demagnetization.

How to Choose the Right Coating for neodymium segment magnets

● Nickel: General choice, rust and wear resistant, bright silver appearance,Corrosion resistant coating

● Epoxy: Black or gray, suitable for wet/chemical environments

● Zinc: low cost, but not as corrosion resistant as nickel

● Gold / Chrome: Can be used for medical devices or high-end decorative parts

Magnetization Direction: What Industrial Buyers Must Know?

● Radial Magnetization

Features: The magnetization direction is perpendicular to the arc surface. One arc surface is north-pole, and the other arc surface is south-pole.

Applications: Motor rotors.

● Axial Magnetization

Features: The magnetization direction is parallel to the magnet axis. The upper surface of the entire arc segment is north-pole, and the lower surface is south-pole (or vice versa).

Applications: Disc motors, magnetic couplers, sensors.

● Multipole Magnetization

Features: Multiple north and south poles are distributed alternately along the length of a single arc segment.

Applications: Precision servo motors and brushless motors

How do we ensure the quality of segment magnets?

● High-precision calipers for dimensional measurement

● Salt spray testing

● Gaussmeter and fluxmeter for magnetic properties

● High-precision electronic balance for weighing

Segment Magnet Selection Guide for High-Speed Motors/High-Temperature Operating Conditions

● Material: SH and UH series NdFeB are preferred. Samarium-cobalt is recommended for high-temperature operation above 180°C, offering stable performance but at a higher cost.

● Coating: Standard nickel-copper-nickel with salt spray testing.

● Certification: IATF16949 is essential.