Rectangular Neodymium Magnets Manufacturer & Custom Supplier – China

Huizhou Fullzen Technology -Your Trusted China Manufacturer for Custom Rectangular Neodymium Magnets, Delivering High-Performance Ndfeb Magnet Solutions Worldwide. Request a Free Sample to Test Quality Before Bulk Orders! Discover why rectangular neodymium magnets are the top choice for industrial, commercial, and DIY projects—offering unmatched strength, precision, and versatility.

Our Rectangular Neodymium Magnet Samples

We offer a wide range of rectangular neodymium magnets in sizes from Small to large, grades from N35 magnet to N52 magnet. Request a free sample to test magnetic strength and suitability before placing bulk orders.we cover the full spectrum of rectangular NdFeB solutions.

Rectangular Neodymium Magnet

Rectangular Magnets

Ni-Cu-Ni Plated NdFeB Magnet

Strong Rectangular Magnet

Request a Free Sample – Test Our Quality Before Bulk Order

Custom Rectangular Neodymium Magnet – Process Guide

Our production process is as follows: After the customer provides drawings or specific requirements, our engineering team will review and confirm them. After confirmation, we will make samples to ensure that all products meet the standards. After the sample is confirmed, we will carry out mass production, and then pack and ship to ensure efficient delivery and quality assurance.

Our MOQ is 100pcs,We can meet customers' small batch production and large batch production. The normal proofing time is 7-15 days. If there is magnet stock, the proofing can be completed. within 3-5 days. The normal production time of bulk orders is 15-20 days. If there is magnet inventory and forecast orders, the delivery time can be advanced to about 7-15 days.

What Are Rectangular Neodymium Magnets?

Definition

Rectangular neodymium magnets, also known as neodymium bar magnets or block magnets, are high-performance Ndfeb magnets engineered with a rectangular form factor. Composed of neodymium, iron, and boron, these strong magnets offer exceptional magnetic strength relative to their size, outperforming traditional magnets like ferrite counterparts.Available in diverse specifications – from small and thin designs to heavy-duty N52 neodymium blocks – they cater to a wide range of applications. Grades including N35 magnet, N42 neodymium , and N52 neodymium define their performance, with N52 being the most powerful option for demanding uses.

Shape types

"Rectangular" is an umbrella term that encompasses a variety of refined geometric profiles, each with distinct magnetic field characteristics and application scenarios. Understanding these subtypes is crucial for selecting the most suitable powerful magnet for your project.It is centered around a rectangular geometric framework; essentially, it involves adding functional designs to the basic types to meet the specific installation and application needs of different industries.

Key Advantages:

Strong magnetism & space-saving: Small in size yet high in magnetic force, suitable for space-constrained scenarios.

Stable performance: The rectangular structure ensures uniform magnetic field, ideal for precision needs such as sensors and magnetic latches.

Flexible customization: Size, coating and magnetization direction can be adjusted as needed, meeting different scenarios like industrial and daily use.

Durable & long-lasting: Made of high-purity NdFeB material with protective coatings , it is rust and wear resistant.

Versatile: industrial sector, electronic field, precision equipment, and automotive field.

Technical Specifications

Applications of Rectangular Neodymium Magnets

Why Choose Us as Your Rectangular Neodymium Magnets Manufacturer?

As a Magnet manufacturer factory, we have our own Factory based in China,and we can provide you OEM/ODM services.

Source Manufacturer: Over 10 years of experience in magnet production, ensuring direct pricing and consistent supply.

Customization: Supports different shapes, sizes, coatings, and magnetization directions.

Quality Control: 100% testing of magnetic performance and dimensional accuracy before shipment.

Bulk Advantage: Automated production lines enable stable lead times and competitive pricing for large orders.

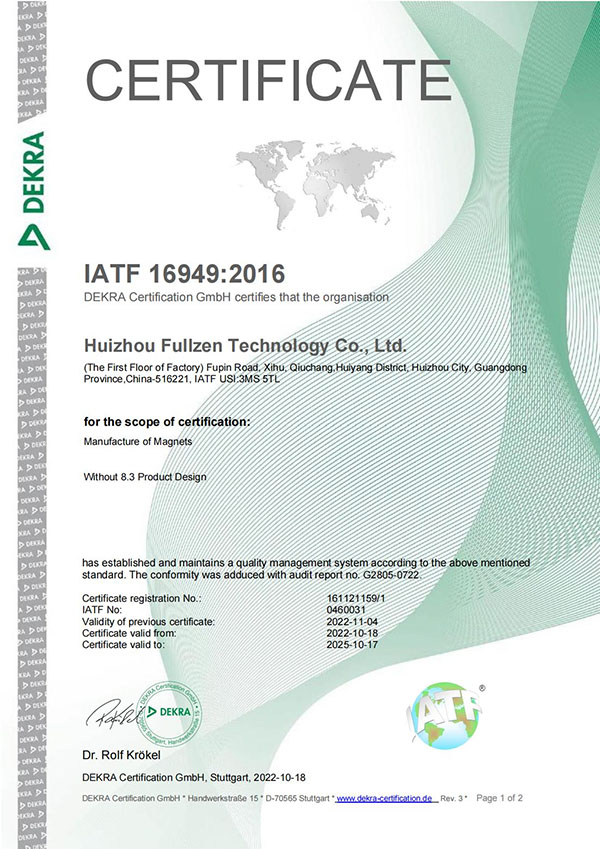

IATF16949

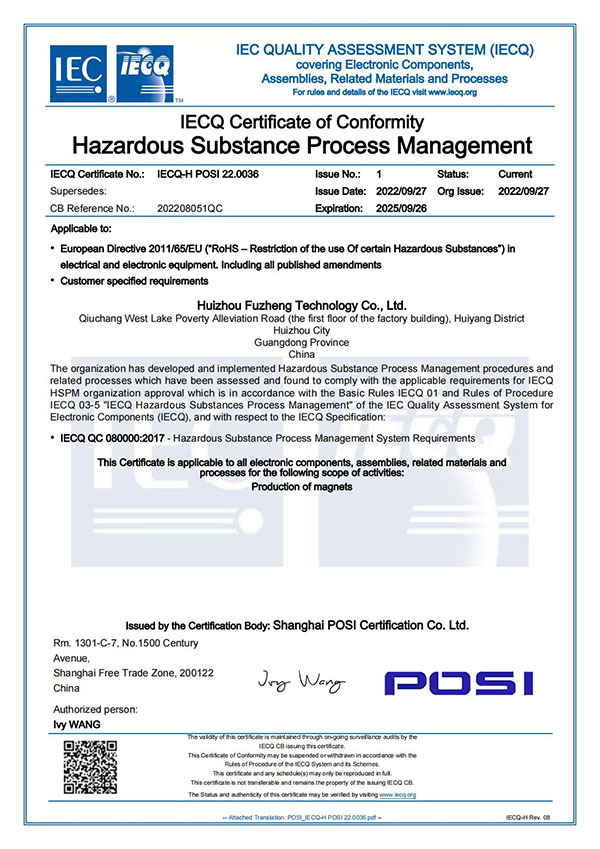

IECQ

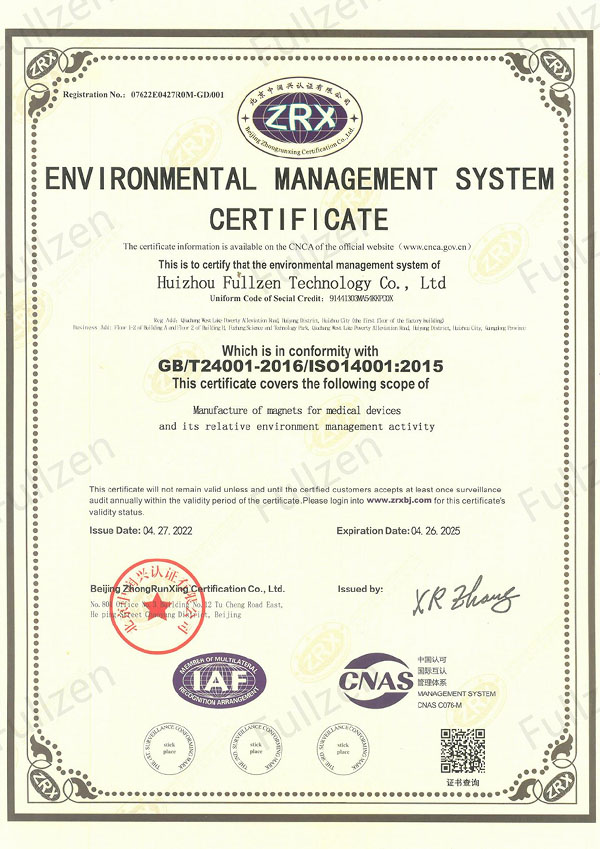

ISO9001

ISO13485

ISOIEC27001

SA8000

Full Solutions From Neodymium Magnet Manufacturer

Fullzen Technology is ready to help you with your project by developing and manufacturing Neodymium Magnet. Our assistance can help you complete your project on time and within budget. We have several solutions to help you succeed.

Supplier Management

Our excellent supplier management and supply chain control management can help our clients to obtain a quick and accurate delivery of quality products.

Production Management

Every aspect of production is handled under our supervision for uniform quality.

Strict Quality Management And Testing

We have a well-trained and professional (Quality Control) quality management team. They are trained to manage the processes of material procurement, finished product inspection, etc.

Custom Service

We do not only provide you with a high-quality magsafe rings but also offer you custom packaging and support.

Document Preparation

We will prepare the complete documents, such as bill of material, purchase order, production schedule, etc., according to your market requirements.

Approachable MOQ

We can meet most customers' MOQ requirements, and work with you to make your products unique.

Packaging details

Start Your OEM/ODM Journey

FAQs about Rectangular Neodymium Magnets

We offer flexible MOQs, starting from small batches for prototyping to large-volume orders.

Standard production time is 15-20 days. With stock, delivery can be as fast as 7–15 days.

Yes, we provide free samples for qualified B2B clients.

We can provide zinc coating, nickel coating, chemical nickel, black zinc and black nickel, epoxy, black epoxy, gold coating etc...

Thicker magnets generally offer higher pull force, but optimal thickness depends on the application.

Yes, with appropriate coatings (e.g., epoxy or parylene), they can resist corrosion and perform reliably in harsh conditions.

We use non-magnetic packaging materials and shielding boxes to prevent interference during transit.

Professional Knowledge & Buying Guide for Industrial Buyers

Magnetic Strength vs. Thickness

The thickness of a Rectangular Neodymium Magnets significantly influences its magnetic output. Thicker magnets generally provide higher pull force, but the relationship is not always linear. Selecting the right thickness involves balancing space constraints with performance requirements.

Coating Selection & Lifespan in Rectangular Neodymium Magnets

Different coatings offer varying levels of protection:

- Nickel: Good overall corrosion resistance, silver appearance.

- Epoxy: Effective in humid or chemical environments, available in black or gray.

- Parylene: Superior protection for extreme conditions, often used in medical or aerospace applications.

Selecting the correct protective coating is crucial. A nickel plating is common for humid environments, while more resistant coatings like epoxy, gold, or PTFE are essential for acidic/alkaline conditions. Coating integrity without damage is paramount.

Custom application cases of Rectangular Neodymium Magnets

● Hidden Magnetic Closure for Packaging:Thin magnets embedded in luxury packaging for a seamless look.

● Industrial Mold Clamping:Flat magnets used in jigs and fixtures for secure, quick-release holding.

●Ultra-Thin Magnets in Electronics: Integrated into smartphones, wearables, and sensors where space is critical.

Your Pain Points and Our Solutions

● Magnetic strength not meeting requirements → We offer custom grades and designs.

● High cost for bulk orders → Minimum cost production that meets requirements.

● Unstable delivery → Automated production lines ensure consistent and reliable lead times.

Customization Guide – How to Communicate Efficiently with Suppliers

● Dimensional drawing or specification (with Dimensional unit)

● Material grade requirements (e.g. N42 / N52)

● Magnetization direction description (e.g. Axial)

● Surface treatment preference

● Packaging method (bulk, foam, blister, etc.)

● Application scenario (to help us recommend the best structure)