China Threaded Neodymium Magnets Supplier-Custom Threaded Bushing Neodymium Pot Magnet

As a threaded neodymium magnets manufacturer and threaded neodymium magnets supplier,we provide magnets more than 100 countries.We professional produce threaded neodymium magnets,U shape magnets,disc magnets,cylinder magnets,ring magnets and so on.We support custom threaded bushing neodymium pot magnet,custom shape,thickness,logo.

Our Threaded Neodymium Magnets Sample

We provide a variety of threaded neodymium magnets samples in different sizes, grades (N35–N52), and coatings. You can request a free sample to test magnetic strength and fit before placing bulk orders.

Encased Neodymium Magnet with Threaded Stud

Neodymium Magnets with Threaded Hole

Custom Threaded Bushing Neodymium Pot Magnet

Threaded Bushing Neodymium Pot Magnet

Request a Free Sample – Test Our Quality Before Bulk Order

Custom Threaded Neodymium Magnets – Process Guide

Our production process is as follows: After the customer provides drawings or specific requirements, our engineering team will review and confirm them. After confirmation, we will make samples to ensure that all products meet the standards. After the sample is confirmed, we will carry out mass production, and then pack and ship to ensure efficient delivery and quality assurance.

Our MOQ is 100pcs,We can meet customers' small batch production and large batch production. The normal proofing time is 7-15 days. If there is magnet stock, the proofing can be completed. within 3-5 days. The normal production time of bulk orders is 15-20 days. If there is magnet inventory and forecast orders, the delivery time can be advanced to about 7-15 days.

Applications of Threaded Neodymium Magnets

Threaded Neodymium Magnets Manufacturer | Custom & Wholesale Supplier from China

As a Magnet manufacturer factory, we have our own Factory based in China,and we can provide you OEM/ODM services.

High-performance neodymium material: N35–N52 optional, supports high temperature and anti-corrosion coating (nickel plating, epoxy, etc.).

Customization flexibility: size/coating/magnetizing direction/logo can all be customized.

Rich export experience: large batch quantities exported to Europe, America, Japan, South Korea,Pakistan,the Middle East, etc.

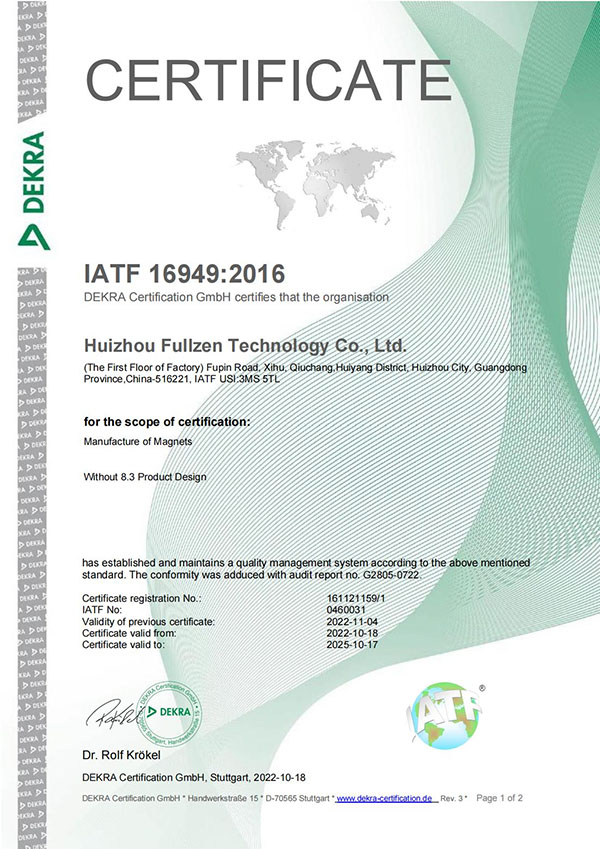

IATF16949

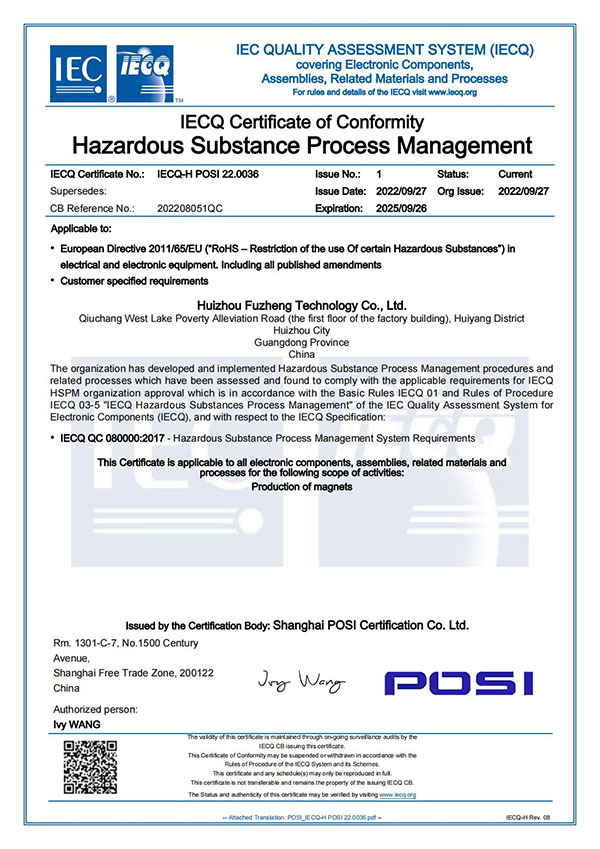

IECQ

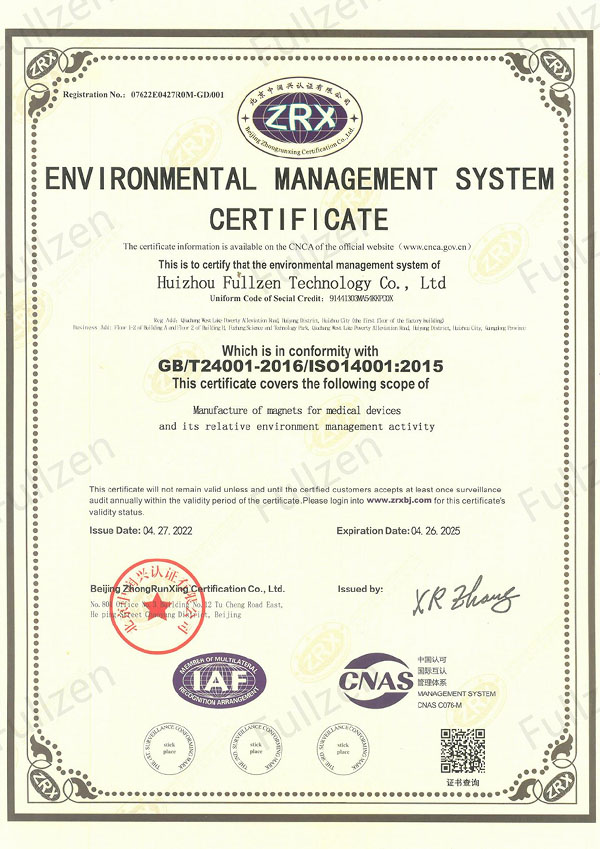

ISO9001

ISO13485

ISOIEC27001

SA8000

Full Solutions From Neodymium Magnet Manufacturer

Fullzen Technology is ready to help you with your project by developing and manufacturing Neodymium Magnet. Our assistance can help you complete your project on time and within budget. We have several solutions to help you succeed.

Supplier Management

Our excellent supplier management and supply chain control management can help our clients to obtain a quick and accurate delivery of quality products.

Production Management

Every aspect of production is handled under our supervision for uniform quality.

Strict Quality Management And Testing

We have a well-trained and professional (Quality Control) quality management team. They are trained to manage the processes of material procurement, finished product inspection, etc.

Custom Service

We do not only provide you with a high-quality magsafe rings but also offer you custom packaging and support.

Document Preparation

We will prepare the complete documents, such as bill of material, purchase order, production schedule, etc., according to your market requirements.

Approachable MOQ

We can meet most customers' MOQ requirements, and work with you to make your products unique.

Packaging details

Start Your OEM/ODM Journey

FAQs about Threaded Neodymium Magnets

Our standard MOQ for threaded neodymium magnets is usually 1000 pieces per specification. However, we understand custom needs and can support smaller trial orders or samples for qualified projects. Please contact us with your requirements for a personalized quote.

The production cycle generally ranges from 15 to 30 working days after confirming all specifications and receiving deposit. Lead time depends on order quantity, magnet grade, threading complexity, and coating type. We offer expedited options for urgent projects—please inquire.

Yes, we support full customization of thread size, pitch, and type—including metric (M2, M3, M4, etc.) and imperial (UNC, UNF) standards. Please provide detailed drawings or specifications to ensure precise matching to your application.

Our threaded neodymium magnets are designed to be compatible with most standard mechanical fasteners and parts, provided correct thread specifications are provided. For special requirements, we recommend sharing your assembly details or samples for verification.

Our threaded neodymium magnets undergo rigorous quality control and testing, and comply with ISO 9001 standards. We can provide SGS, RoHS, REACH certification reports upon request to assure material safety and performance.

Yes, our engineering team offers design support to optimize magnet size, thread design, and magnetization for your specific application. Please contact us to discuss your project in detail.

Yes, sample production is available. Samples can be made according to your specifications to verify fit, thread accuracy, magnetic strength, and coating quality before full production.

Please provide detailed technical drawings showing magnet dimensions, thread size/type, magnet grade (e.g., N35, N52), magnetization direction, and coating preferences. CAD or STEP files are preferred for precise manufacturing.

Common coatings include nickel (Ni), zinc (Zn), epoxy resin, and special anti-corrosion coatings. For harsh or outdoor environments, epoxy or custom coatings are recommended. We can advise the best coating based on your application and environmental conditions.

Professional Knowledge & Buying Guide for Industrial Buyers

How Thread Design Affects Magnetic Field Distribution and Mechanical Bonding Strength?

● The spiral thread structure enhances the directional magnetic field through its helical arrangement.

● The arc-shaped tooth profile reduces stress concentration, optimizes the magnetic path, and prevents material cracking.

How to Choose the Right Coating for Threaded Neodymium Magnets?

● Nickel: General choice, rust and wear resistant, bright silver appearance,Corrosion resistant coating

● Epoxy: Black or gray, suitable for wet/chemical environments

● Zinc: low cost, but not as corrosion resistant as nickel

● Gold / Chrome: Can be used for medical devices or high-end decorative parts

The Impact of Different Thread Specifications on Assembly Compatibility and Mechanical Strength

● Coarse threads: Suitable for general mechanical connections (such as in construction and automobiles) due to their good interchangeability, low cost, and ease of operation.

● Fine threads: Used in precision machinery (such as optical instruments and thin-walled parts) due to their improved self-locking properties and higher adjustment accuracy.

How to Choose the Most Suitable Magnet Grade Based on Cost and Performance Requirements When Purchasing

● N35: Lower price, weaker magnetic force, suitable for basic magnetism (such as packaging and light suction)

● N42: Higher price than N35, suitable for brushless motors and precision equipment

Purchase Recommendations

● Clarify requirements: List key parameters such as the specific application scenario, space constraints, and budget.

● Prioritize communication: Discuss details such as material properties and processing techniques with the manufacturer to ensure the selected product meets your specific needs.

Customization Guide – How to Communicate Efficiently with Suppliers

● Dimensional drawing or specification (with Dimensional unit)

● Material grade requirements (e.g. N42 / N52)

● Magnetization direction description (e.g. Axial)

● Surface treatment preference

● Packaging method (bulk, foam, blister, etc.)

● Application scenario (to help us recommend the best structure)