U Shaped Neodymium Magnets Manufacturer – Custom & Wholesale from China

Being a leading Permanent magnets Factory, we specialize in manufacturing high-performance U shaped neodymium magnets also known as Horse shoe magnetand other magnet such as Educational magnets,Disc,Block,Round Etc...Our Powerful magnet face to All over the world, mainly ship to North/South America,Europe, Asian also Indiamart. Our focus on magnets gives our customers full confidence in us. About the magnet we can customized the shape,coating,grade,and magnetizing diretion.So we can meet customers' high-precision requirements and some special requirements.When we're facing 100 customer's requirement we'll also have 100 or more than 100 solution for customer.

Our U Shaped Neodymium Magnet Samples

We provide a variety of U shaped magnet samples in different sizes, grades (N35–N52), and coatings. You can request a free sample to test magnetic strength and fit before placing bulk orders.

Zinc U shape Neodymium magnet

Ni-Cu-Ni U shape neodymium magnet

super powerful neodymium magnets

N52 U shape neodymium magnet

neodymium magnets big

Horse shoe magnet

U shape Neodymium magnet with hole

Request a Free Sample – Test Our Quality Before Bulk Order

Custom U Shaped Neodymium Magnets – Process Guide

Our production process is as follows: After the customer provides drawings or specific requirements, our engineering team will review and confirm them. After confirmation, we will make samples to ensure that all products meet the standards. After the sample is confirmed, we will carry out mass production, and then pack and ship to ensure efficient delivery and quality assurance.

Our MOQ is 100pcs,We can meet customers' small batch production and large batch production. The normal proofing time is 7-15 days. If there is magnet stock, the proofing can be completed. within 3-5 days. The normal production time of bulk orders is 15-20 days. If there is magnet inventory and forecast orders, the delivery time can be advanced to about 7-15 days.

Applications of U Shaped Neodymium Magnets

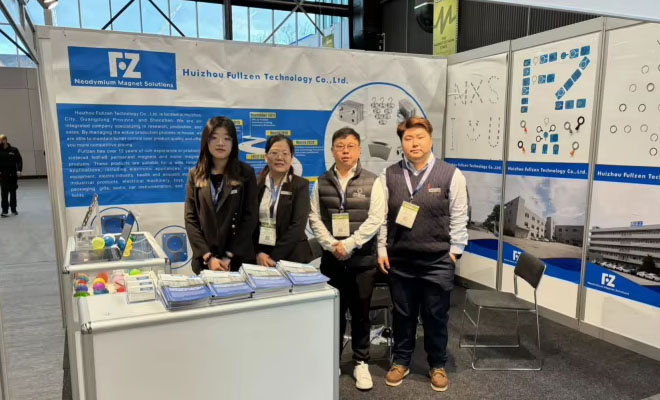

Why Choose Us as Your U Shaped Neodymium Magnet Manufacturer?

As a Magnet manufacturer factory, we have our own Factory based in China,and we can provide you OEM/ODM services.

High-performance neodymium material: N35–N52 optional, supports high temperature and anti-corrosion coating (nickel plating, epoxy, etc.).

Customization flexibility: size/coating/magnetizing direction/logo can all be customized.

Rich export experience: large batch quantities exported to Europe, America, Japan, South Korea,Pakistan,the Middle East, etc.

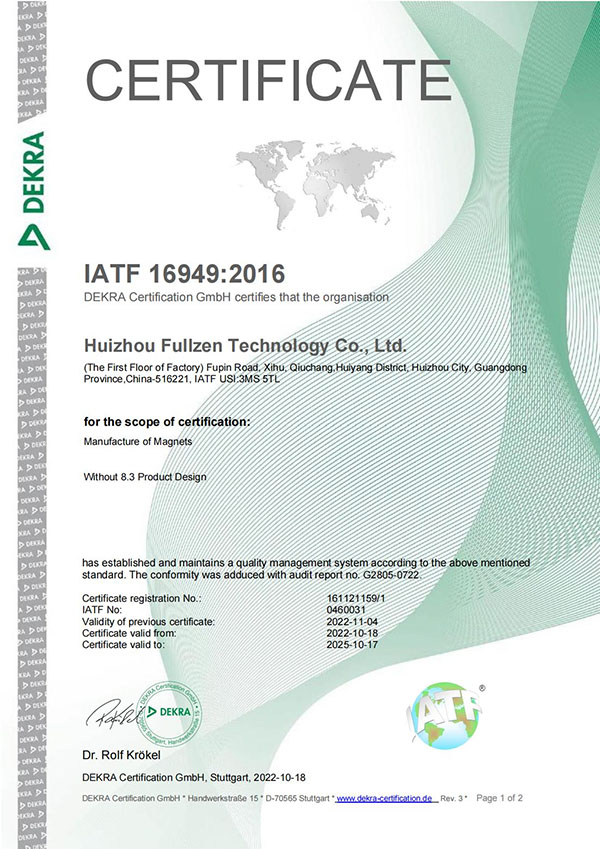

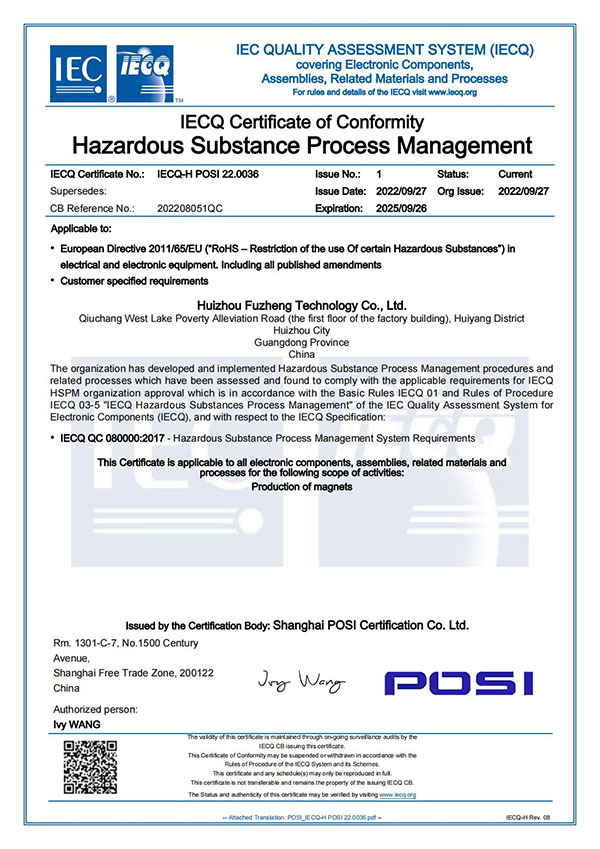

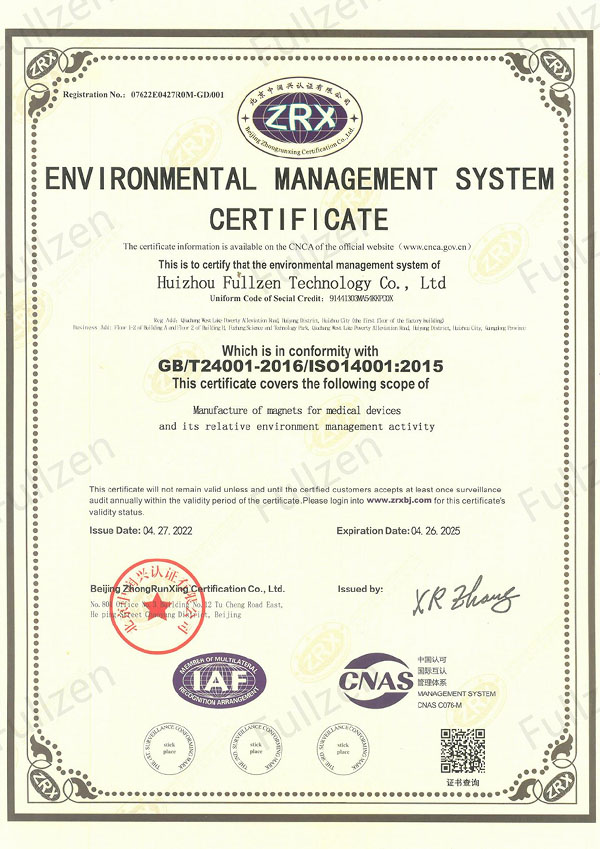

IATF16949

IECQ

ISO9001

ISO13485

ISOIEC27001

SA8000

Full Solutions From Neodymium Magnet Manufacturer

Fullzen Technology is ready to help you with your project by developing and manufacturing Neodymium Magnet. Our assistance can help you complete your project on time and within budget. We have several solutions to help you succeed.

Supplier Management

Our excellent supplier management and supply chain control management can help our clients to obtain a quick and accurate delivery of quality products.

Production Management

Every aspect of production is handled under our supervision for uniform quality.

Strict Quality Management And Testing

We have a well-trained and professional (Quality Control) quality management team. They are trained to manage the processes of material procurement, finished product inspection, etc.

Custom Service

We do not only provide you with a high-quality magsafe rings but also offer you custom packaging and support.

Document Preparation

We will prepare the complete documents, such as bill of material, purchase order, production schedule, etc., according to your market requirements.

Approachable MOQ

We can meet most customers' MOQ requirements, and work with you to make your products unique.

Packaging details

Start Your OEM/ODM Journey

FAQs about U Shaped Neodymium Magnets

Yes, we support free samples for the sustainable development of our customers.

Normal Bulk orders delivery time is 15-20 days, but if you can provide a forecast plan before placing an order or if we have stock, the delivery date can be advanced.

NdFeB magnets are not as heat-resistant as Alnico magnets, which can withstand temperatures of 450 to 550 °C. NdFeB magnets generally withstand temperatures of around 80 to 220°C.

We can provide zinc coating, nickel coating, chemical nickel, black zinc and black nickel, epoxy, black epoxy, gold coating etc...

The magnetic field of each shape of magnet is different. We can customize the shape and magnetization direction to meet customer requirements.

Professional Knowledge & Buying Guide for Industrial Buyers

Why U Shaped Design? Magnetic Field Behavior Explained?

● The U-shaped structure helps to concentrate the magnetic flux, resulting in a stronger, more focused holding field. This design increases the efficiency of the magnet in clamping applications.

● Suitable for bipolar adsorption scenarios (such as fixtures and jigs)

● Better directionality and stability than traditional bar Magnet

How to Choose the Right Coating for U Shaped Magnets?

● Nickel: General choice, rust and wear resistant, bright silver appearance,Corrosion resistant coating

● Epoxy: Black or gray, suitable for wet/chemical environments

● Zinc: low cost, but not as corrosion resistant as nickel

● Gold / Chrome: Can be used for medical devices or high-end decorative parts

Magnetization Direction: What Industrial Buyers Must Know?

● Axial: points from one arm to the other, suitable for clamping applications

● Diametrical: Less commonly used for U-shaped, but customizable

● Multi-pole: for special sensors/motors

If you can provide drawings or explain the purpose, we can help you determine the most suitable magnetization direction and solution.

Pull Force Calculation for U Shaped Magnets – Don’t Be Misled

U-shaped magnets (also called horseshoe magnets) are widely used in clamping, supporting, lifting and sensing applications due to their unique magnetic field concentrating properties. However, there is a common misconception when it comes to understanding and calculating their pull force. Many users believe that pull force ratings for magnets of different shapes and constructions are universal or directly comparable. This is not the case.

What is Pull Force?

Pull force is the maximum force required to separate a magnet from a steel surface, usually measured in kilograms or pounds. This depends on several factors:

● Magnet material and grade (e.g., NdFeB N52 vs. Alnico 5)

● Condition of contacting surfaces (clean, flat, thick, uncoated steel = best)

● Direction of force (straight-line pull is ideal; sideways shear can significantly reduce holding force)

● Air gaps and coatings (even thin coatings or gaps can degrade performance)

What’s special about U-shaped magnets

U-shaped magnets are designed to direct the magnetic field from both poles to the same surface, effectively concentrating the field into a smaller area. This construction creates a strong local magnetic field, especially at the gap between the poles.

However, this construction adds complexity to accurately measuring pull force:

● The working gap between the poles affects the magnetic field concentration.

● The contact of the magnet to the surface is not always uniform.

● Magnetic field leakage and edge effects lead to nonlinear force distribution.

Common mistakes in estimating pull force

● Assuming that pull force scales linearly with size.

● Larger U-shaped magnets may not produce correspondingly higher pull forces if the inter-pole gap or surface contact is not optimized.

How to Accurately Measure U-Magnet Pull Force

● Use a calibrated pull gauge and test on a flat, thick, mild steel plate.

● Make sure the poles are in full flush contact with the magnet surface.

● Pull perpendicular to the surface to avoid shear effects.

● If the magnet will operate on painted, curved, or dirty surfaces, test under specific conditions.

Customization Guide – How to Communicate Efficiently with Suppliers

● Dimensional drawing or specification (with Dimensional unit)

● Material grade requirements (e.g. N42 / N52)

● Magnetization direction description (e.g. Axial)

● Surface treatment preference

● Packaging method (bulk, foam, blister, etc.)

● Application scenario (to help us recommend the best structure)