Neodymium Magnet with Hook Manufacturer | Custom & Wholesale Supplier from China

We are a leading manufacturer of neodymium magnets with hooks, offering custom sizes, coatings, and weight capacities for industrial and commercial use. Bulk orders, OEM/ODM, and fast worldwide shipping supported.If you want know more,you can know more about the hook magnet from comparison of common hook types and applications and how to calculate pull force and select the right neodymium magnet with hook.

Our Hook Neodymium Magnet Samples

We provide a variety of Hook magnet samples in different sizes, grades (N35–N52), and coatings. You can request a free sample to test magnetic strength and fit before placing bulk orders.

Strong Hook Neodymium Magnets

Powerful Neodymium Hook Magnets

Strong Magnetic Hooks

Neodymium Pot Magnet with Hook

Request a Free Sample – Test Our Quality Before Bulk Order

Custom Hook Neodymium Magnets – Process Guide

Our production process is as follows: After the customer provides drawings or specific requirements, our engineering team will review and confirm them. After confirmation, we will make samples to ensure that all products meet the standards. After the sample is confirmed, we will carry out mass production, and then pack and ship to ensure efficient delivery and quality assurance.

Our MOQ is 100pcs,We can meet customers' small batch production and large batch production. The normal proofing time is 7-15 days. If there is magnet stock, the proofing can be completed. within 3-5 days. The normal production time of bulk orders is 15-20 days. If there is magnet inventory and forecast orders, the delivery time can be advanced to about 7-15 days.

Applications of Hook Neodymium Magnets

Why Choose Us as Your Hook Neodymium Magnet Manufacturer?

Source Factory: High-volume production capabilities + CNC

Customization Capabilities: OEM/ODM support, engineer-assisted design

Quality Assurance: Tensile testing, coating corrosion resistance testing

Main Export Markets: Europe, America, Southeast Asia, industrial/retail customers

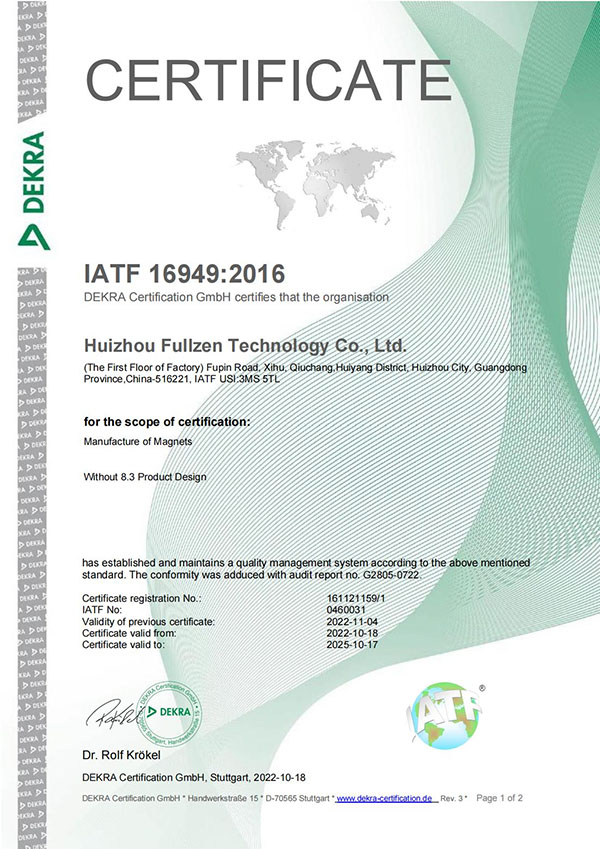

IATF16949

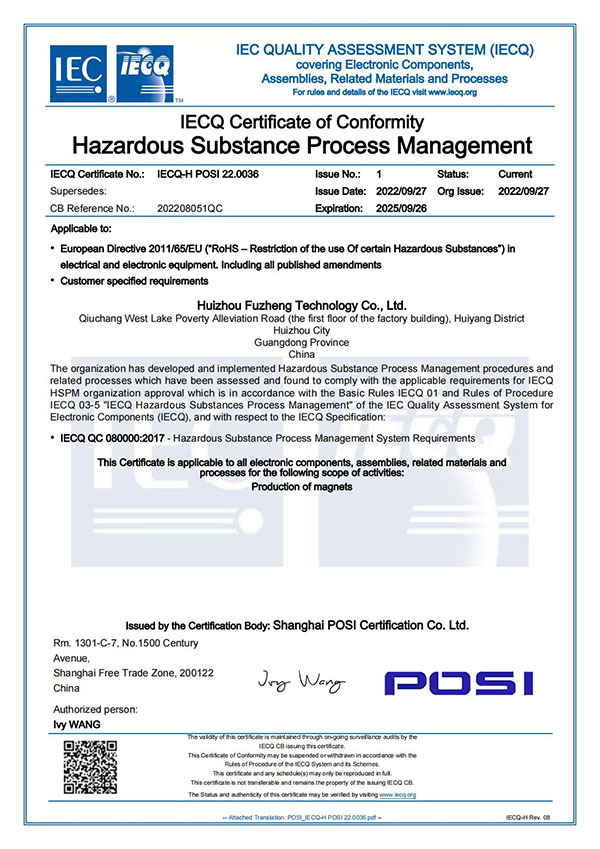

IECQ

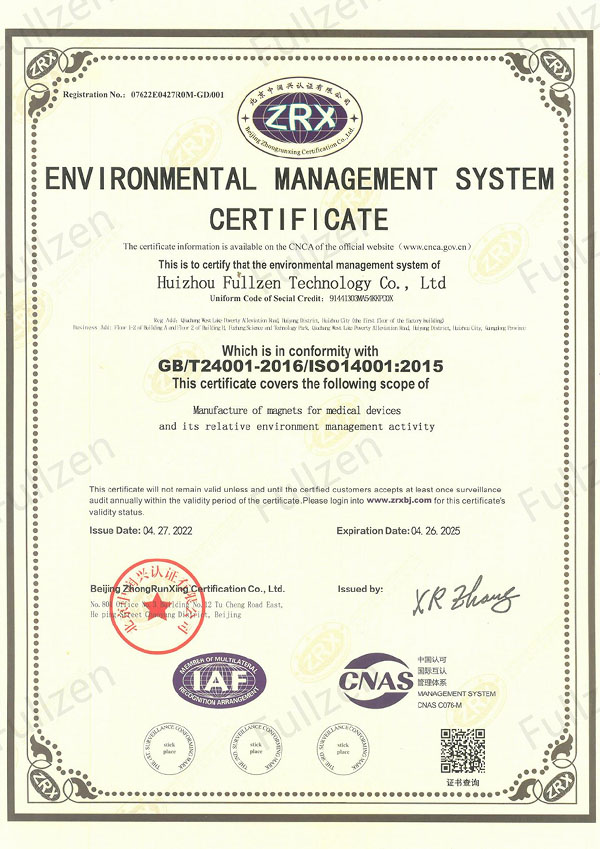

ISO9001

ISO13485

ISOIEC27001

SA8000

Full Solutions From Neodymium Magnet Manufacturer

Fullzen Technology is ready to help you with your project by developing and manufacturing Neodymium Magnet. Our assistance can help you complete your project on time and within budget. We have several solutions to help you succeed.

Supplier Management

Our excellent supplier management and supply chain control management can help our clients to obtain a quick and accurate delivery of quality products.

Production Management

Every aspect of production is handled under our supervision for uniform quality.

Strict Quality Management And Testing

We have a well-trained and professional (Quality Control) quality management team. They are trained to manage the processes of material procurement, finished product inspection, etc.

Custom Service

We do not only provide you with a high-quality magsafe rings but also offer you custom packaging and support.

Document Preparation

We will prepare the complete documents, such as bill of material, purchase order, production schedule, etc., according to your market requirements.

Approachable MOQ

We can meet most customers' MOQ requirements, and work with you to make your products unique.

Packaging details

Start Your OEM/ODM Journey

FAQs about Hook Neodymium Magnets

With high-performance neodymium magnets, the holding force typically ranges from 5kg to 100kg. We can provide products with different pull forces to meet your needs.

Standard diameters (such as 16mm, 20mm, 32mm, 75mm, etc.)

Hook types (open hook, closed hook, swivel hook, stainless steel hook)

support customer-specified size, color, coating, and packaging

Stainless steel housings offer superior corrosion resistance, mechanical properties, and lifespan, but are also the most expensive.

Nickel-plated housings offer both good corrosion resistance and decorative appeal, while galvanized housings are suitable for general outdoor use and offer low-cost corrosion protection.

Epoxy-coated housings offer highly customizable appearance but suffer from poor mechanical properties and damage resistance.

Application recommendations: Nickel plating is recommended for indoor use, while epoxy or stainless steel is recommended for outdoor or humid environments.

Yes,we support sample order.

100 pieces.

Define core needs: Identify the primary purpose (e.g., securing components, resisting separation, or withstanding dynamic loads) and calculate the maximum expected pull force your application will encounter (including static loads, vibrations, or shocks).

Factor in safety margins: Select a pull force rating 2–5 times higher than the maximum expected load (depending on criticality—e.g., medical or aerospace applications demand larger margins to prevent failure).

Consider environment and materials: Account for conditions like temperature, corrosion, or wear (which weaken materials) and ensure the component’s material/design (e.g., metal vs. plastic, fastener type) can sustain the chosen pull force under these conditions.

Reference standards: Align with industry norms (e.g., ISO, ASTM) for your field (e.g., electronics, construction) to ensure compatibility and safety.

We have tensile testing, coating salt spray testing, and provide certification (ISO9001, RoHS, SGS)

Sample lead time (5-7 days)

Mass production (15-30 days)

Yes,we have technical team to help you solve the problem.

Professional Knowledge & Buying Guide for Industrial Buyers

Structural Design and Magnetic Force Principles of Neodymium Magnet with Hook

●Structural design: Consists of a neodymium magnet body, a high-strength hook, and a connecting structure, requiring scenario-based selection and balancing magnetic efficiency, load-bearing capacity, and environmental adaptability.

●Fundamentals of magnetic force calculation: Relies on parameters such as remanence and maximum energy product, with higher parameter values indicating stronger magnetic force.

●Factors for magnetic force correction: Actual attractive force is affected by the thickness of the adsorbed object, gaps, material magnetism, and magnet shape, requiring calculation results to be corrected accordingly during design.

Surface Coating Options and Corrosion Resistance for Neodymium Magnet with Hook

● Nickel: General choice, rust and wear resistant, bright silver appearance,Corrosion resistant coating

● Epoxy: Black or gray, suitable for wet/chemical environments

● Zinc: low cost, but not as corrosion resistant as nickel

● Gold / Chrome: Can be used for medical devices or high-end decorative parts

Load Capacity and Safety Factors When Using Neodymium Magnet with Hook

● A magnet hook's strength depends on:

Magnet pull force (based on size/material)

Hook strength (material/shape)Use the weaker value.

● Safety Rules

Actual max load = (Calculated strength) ÷ 1.2-1.5

(Accounts for wear/overload)

● Safety Design

●Anti-slip features

●Even stress distribution

●Weather-resistant materials

●(For long-term reliability)

Key numbers: Always use 1.2-1.5× safety margin.

Hook Types and Customization Parameters of Neodymium Magnet with Hook

Hook Design Options

● Standard types: J-hook, eye hook, threaded hole hook; custom designs available

● Key parameters: Hook opening diameter (5-20mm), bend angle (90°-180°), reinforced neck design

Magnet Customization

● Adjustable diameter/thickness (typical range: Φ10-50mm × 3-15mm)

● Magnet grades (N35-N52 available), coatings (nickel/zinc/epoxy)

Load Capacity Matching Principle

● Combined calculation of magnetic force + hook mechanical strength (lower value governs

● Standard 1.5x safety factor; +20% margin required for high temp/humidity environments

(Note: Custom orders require application parameters: load type, environmental conditions, mounting method)

High-Temperature and Special Environment Applications of Neodymium Magnet with Hook

High-Temperature Environments

● Standard models: ≤80°C | High-temp models: up to 200°C

● Magnetic strength decreases by 0.1% per 1°C rise

● Epoxy coating recommended

Humid/Corrosive Environments

● Use stainless steel hooks (304/316 grade)

● Coating priority: Epoxy > Zinc > Nickel

Vibratory Conditions

● Anti-slip rubber pads required

● Safety factor must be ≥2.0

Other Considerations

● Strong magnetic fields: Maintain 50cm clearance

● Ultra-low temps (<-40°C): Avoid zinc plating

Note: Custom solutions require specific environmental parameters.

Quality Control and Testing Standards for Bulk Production of Neodymium Magnet with Hook

Raw Material Control

● Magnet: Verify NdFeB grade (N35-N52), coating type (Ni/Zn/Epoxy) and thickness (≥12μm)

● Hook: Validate 304/316 stainless steel material certificates with tensile strength ≥500MPa

In-Process Inspection

● Dimensional tolerance: Magnet diameter ±0.1mm, hook opening precision ±0.2mm

● Magnetic force test: 5% batch sampling with Gauss meter (measured adhesion force ≥1.2x nominal value)

● Coating adhesion: Cross-cut test (ASTM D3359 standard, rating ≥4B)

Final Product Inspection

● Load test: Withstand 1.5x rated load for 24 hours without detachment/deformation

● Salt spray test: 48-hour exposure for nickel coating (ASTM B117 standard, no rust)

● Aging test: ≤5% magnetic loss after 500 hours at 85°C/85%RH

Packaging & Traceability

● Individual shock-proof packaging with laser-marked batch numbers (traceable to production date/line)

Note: Monthly third-party testing (SGS/BV) with full inspection on critical parameters.

Customization Guide – How to Communicate Efficiently with Suppliers

● Dimensional drawing or specification (with Dimensional unit)

● Material grade requirements (e.g. N42 / N52)

● Magnetization direction description (e.g. Axial)

● Surface treatment preference

● Packaging method (bulk, foam, blister, etc.)

● Application scenario (to help us recommend the best structure)