Designed and manufactured for your application

Fullzen – Neodymium Custom Industrial Magnet Manufacturer in the China

Fullzen Technology is the professional custom magnet manufacturer in the China, including ndfeb permanent magnets, samarium cobalt magnets,ring magnets,cube magnets,arc magnets,magsafe magnet ring and other magnetic products.

These products can apply in electronic appliances, industrial equipment, electro acoustic industry, health equipment, industrial products, electrical machinery, toys, printing packaging gifts, audio, car instrumentation, 3C digital and other fields.

We use our proven technology and processes to solve your magnet problems, reducing your costs, taking you from prototype to mass production.

We deliver a turnkey service to manage your magnet engineering risks delivering on time and to spec.

Industrial Magnets We Manufacture

Custom neodymium magnets and magnetic assemblies manufactured specifically for your application. Custom Bulk Orders Are Welcome. Manufactured in the China. Total Magnetic Solutions. ISO 9000 Registered. No Minimums. Fast Turnaround.

5 Key Reasons Why Buy

As a professional neodymium magnets manufacturer supplier and factory, our positioning is to be a customer’s technical, production, after-sales, R&D team, quickly and professionally provide various ndfeb magnets solutions to solve various Neo magnets problems encountered by customers. Our customers only need to do a good job in the custom of neodymium magnets, the other things such as controlling cost, neodymium magnets design & solutions, and after-sales, we will help customers deal with it in order to maximize customer benefits.

-

Customization

We have a strong R&D team, and we can develop and produce ndfeb magnets according to drawings or samples provided by customers.

-

Cost

We have a full line of production devices of neodymium magnet, which can effectively reduce production costs.

-

Quality

We have our own testing lab and the advanced and complete inspection equipment, which can ensure the quality of the neodymium magnets.

-

Capacity

Our annual production capacity is over 2000 tons, we can meet the needs of different customers with different purchase quantities.

-

Transport

we have an absolute advantage in the cost of raw materials. Under the same quality, our price is generally 10%-30% lower than the market.

Our Case

our case study show

-

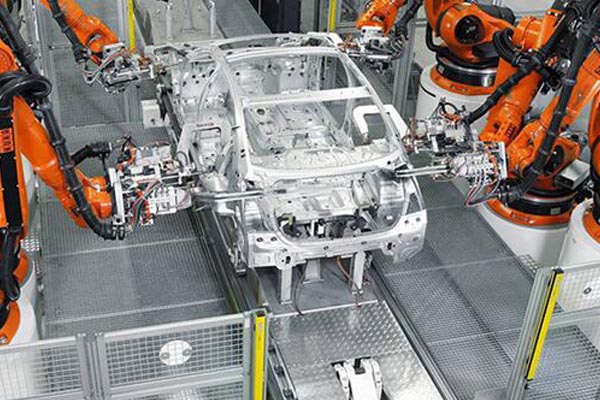

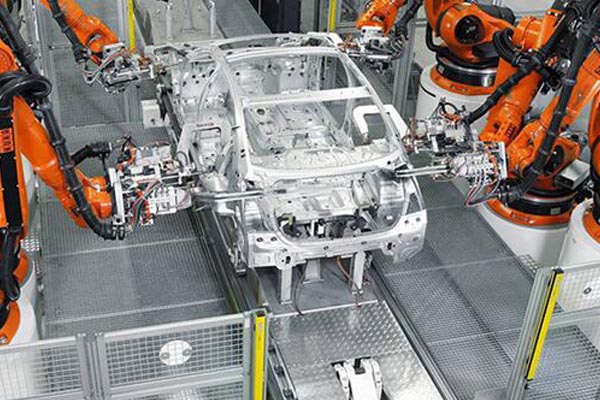

vehicles

Neodymium Magnets are the key components in automotive electronic technology, which have been widely used in automotive, such as automotive safety and information system, electronic control unit, vehicle multimedia system, energy transmission system, etc.view more -

medical devices

Neodymium magnets have numerous applications in the medical field. They can produce a static magnetic field and thus, are commonly used in medical devices such as magnetic resonance imaging (MRI) machines to identify and diagnose arthritis, insomnia, chronic pain syndrome, wound healing, and headache.view more -

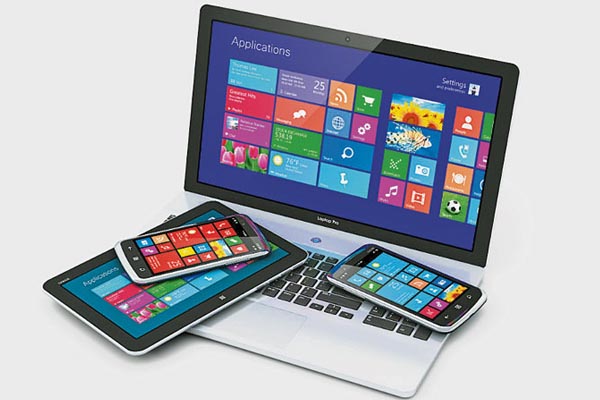

electronic products

Neodymium magnets are made of a combination of iron, boron and neodymium, so their resistance and the diversity of ways in which they can be produced, make their use in everyday life so common;As far as electronic products are concerned, neodymium magnets are basically used in audio equipment such as loudspeaker, receiver, microphone, alarm, stage sound, car sound, etc.view more

Latest News

Check here for recent industry new and our latest updates at China Magnetics.

Also known simply as a neo magnet, a neodymium magnet is a type of rare-earth magnet that’s comprised of neodymium, iron and boron. Although there are other rare-earth magnets — including samarium cobalt — neodymium is by far the most common.

Read More