Neodymium Channel Magnet Manufacturer | Custom Sizes & Bulk Orders from China

China-based OEM manufacturer specializing in high-performance neodymium channel magnets, offering custom sizes (including block magnets) and magnetic strengths (up to grade N52) with nickel-plated or steel-coated finishes. Our heavy-duty channel magnets deliver superior pull force and holding power compared to ceramic alternatives, featuring optimized magnetic fields for industrial applications. We support bulk wholesale orders with fast delivery, providing complete ODM/OEMsolutions including steel channel assembliesand screw-compatible designs for secure mounting systems.

Our Channel Neodymium Magnet Samples

We provide a variety of channel magnet samples in different sizes, grades (N35–N52), and coatings. You can request a free sample to test magnetic strength and fit before placing bulk orders.

neodymium channel magnets

channel neodymium magnets

neodymium magnets hydraulic press channel

Request a Free Sample – Test Our Quality Before Bulk Order

Custom Channel Neodymium Magnets – Process Guide

Our production process is as follows: After the customer provides drawings or specific requirements, our engineering team will review and confirm them. After confirmation, we will make samples to ensure that all products meet the standards. After the sample is confirmed, we will carry out mass production, and then pack and ship to ensure efficient delivery and quality assurance.

Our MOQ is 100pcs,We can meet customers' small batch production and large batch production. The normal proofing time is 7-15 days. If there is magnet stock, the proofing can be completed. within 3-5 days. The normal production time of bulk orders is 15-20 days. If there is magnet inventory and forecast orders, the delivery time can be advanced to about 7-15 days.

What is a Neodymium Channel Magnet?

A channel magnet refers to a magnetic assembly where neodymium (NdFeB) magnets are embedded in steel or aluminum channels. These rare earth channel magnets combine the extreme strength of grade N35-N52 neodymium with structural support for industrial applications.

Ideal for mounting systems, sensors, and automation equipment requiring both magnetic strength and mechanical protection.

Applications of Neodymium Channel Magnets

Neodymium Channel Magnet Production Process & Quality Control

Sintering → Cutting/Machining → Magnetizing → Coating → Packaging

Why Choose Us as Your Channel Neodymium Magnet Manufacturer?

As a Magnet manufacturer factory, we have our own Factory based in China,and we can provide you OEM/ODM services.

High-performance neodymium material: N35–N52 optional, supports high temperature and anti-corrosion coating (nickel plating, epoxy, etc.).

Customization flexibility: size/coating/magnetizing direction/logo can all be customized.

Rich export experience: large batch quantities exported to Europe, America, Japan, South Korea,Pakistan,the Middle East, etc.

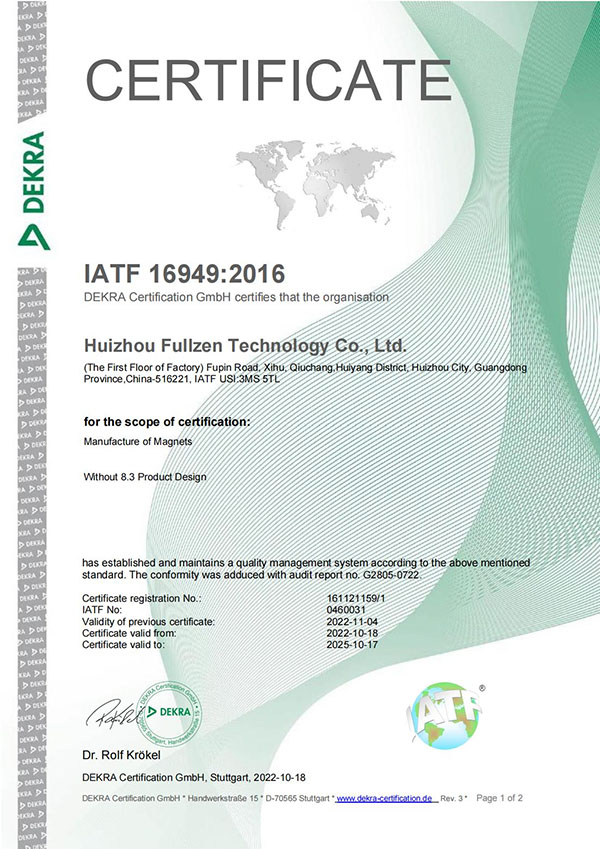

IATF16949

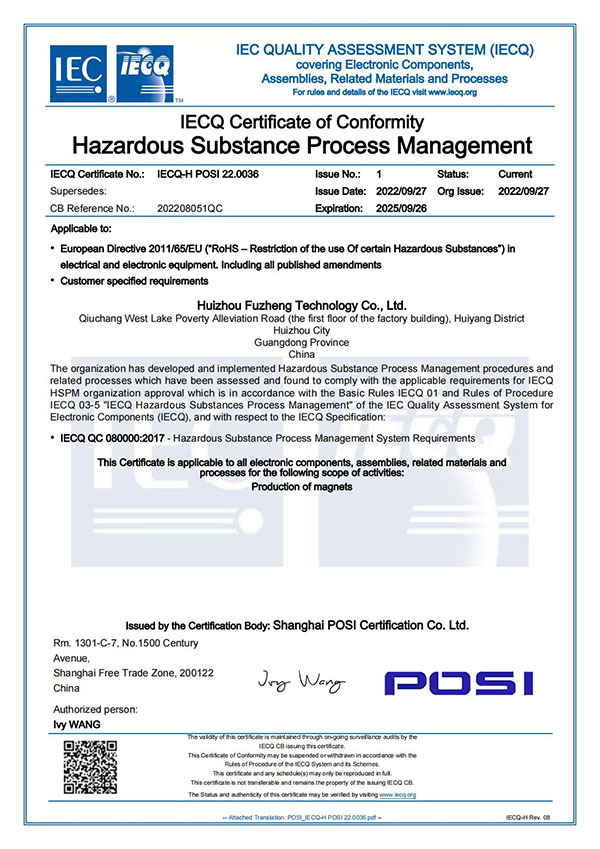

IECQ

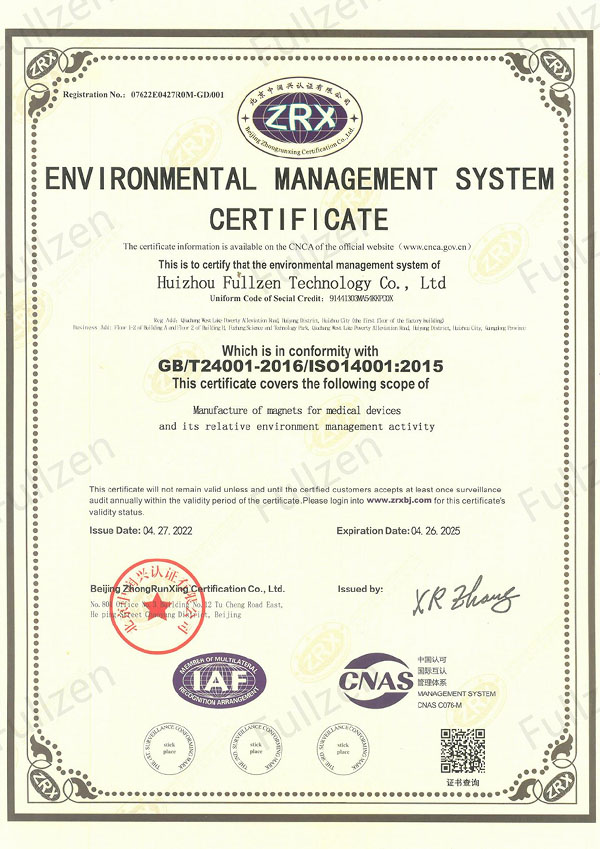

ISO9001

ISO13485

ISOIEC27001

SA8000

Full Solutions From Neodymium Magnet Manufacturer

Fullzen Technology is ready to help you with your project by developing and manufacturing Neodymium Magnet. Our assistance can help you complete your project on time and within budget. We have several solutions to help you succeed.

Supplier Management

Our excellent supplier management and supply chain control management can help our clients to obtain a quick and accurate delivery of quality products.

Production Management

Every aspect of production is handled under our supervision for uniform quality.

Strict Quality Management And Testing

We have a well-trained and professional (Quality Control) quality management team. They are trained to manage the processes of material procurement, finished product inspection, etc.

Custom Service

We do not only provide you with a high-quality magsafe rings but also offer you custom packaging and support.

Document Preparation

We will prepare the complete documents, such as bill of material, purchase order, production schedule, etc., according to your market requirements.

Approachable MOQ

We can meet most customers' MOQ requirements, and work with you to make your products unique.

Packaging details

Start Your OEM/ODM Journey

FAQs about Channel Neodymium Magnets

Yes, we support free samples for the sustainable development of our customers.

Normal Bulk orders delivery time is 15-20 days, but if you can provide a forecast plan before placing an order or if we have stock, the delivery date can be advanced.

NdFeB magnets are not as heat-resistant as Alnico magnets, which can withstand temperatures of 450 to 550 °C. NdFeB magnets generally withstand temperatures of around 80 to 220°C.

We can provide zinc coating, nickel coating, chemical nickel, black zinc and black nickel, epoxy, black epoxy, gold coating etc...

The magnetic field of each shape of magnet is different. We can customize the shape and magnetization direction to meet customer requirements.

Professional Knowledge & Buying Guide for Industrial Buyers

Mechanism of Groove Structure in Magnetic Field Concentration and Force Enhancement

● Magnetic Field Concentration: Grooved structures can concentrate magnetic field lines near the slots, reducing dispersion and creating a stronger localized magnetic field.

● Enhanced Magnetic Force: The edges of the slots generate a more intense magnetic field, increasing strength by 30%-50% compared to flat magnets, making them ideal for high-force applications.

● Optimized Design: Grooves can be paired with multi-pole magnetization to minimize magnetic leakage, though they require more complex machining and cost considerations to balance performance and durability.

How to Choose the Right Coating for Channel Magnets?

● Nickel: General choice, rust and wear resistant, bright silver appearance,Corrosion resistant coating

● Epoxy: Black or gray, suitable for wet/chemical environments

● Zinc: low cost, but not as corrosion resistant as nickel

● Gold / Chrome: Can be used for medical devices or high-end decorative parts

Recommendations for Different Usage Environments of Channel Magnets

● Indoor Environments (Stable Temperature/Humidity)

Recommended Treatment: Nickel Plating (Ni-Cu-Ni)

Advantages: Cost-effective, glossy finish, prevents oxidation. Ideal for electronics and precision instruments.

● Outdoor/High-Humidity Environments (Rain, Moisture)

Recommended Treatment: Epoxy Resin Coating (Black/Gray)

Advantages: Excellent corrosion resistance, withstands salt spray. Suitable for marine equipment and outdoor sensors.

● High-Temperature Environments (80°C+)

ecommended Treatment: Phosphating + High-Temp Epoxy Coating

Advantages: Heat-resistant (150-200°C), prevents thermal oxidation. Used in motors and automotive components.

● Strong Acid/Alkali or Chemical Corrosion Environments

Recommended Treatment: PTFE (Teflon) Coating

Advantages: Chemical-resistant, electrically insulating. Ideal for medical and chemical equipment.

How to Choose Channel Magnet Size, Magnetic Grade and Magnetization Direction According to Application Requirements?

Determine Size Based on Space and Force Requirements

First match the installation space (e.g., motor slot size), then adjust thickness according to magnetic force needs:

- Small gaps: Use thin models (1.5–5mm)

- Strong force needed: Choose thicker versions (5–30mm)

Select Magnetic Grade by Application Scenario

- General use:(e.g., household magnetic holders): N35–N42 (cost-effective)

- Industrial/high-power:(e.g., motors, medical devices): N45–N52 (heat-resistant/strong force)

- High-temperature environments: Choose "H/SH" suffix models (e.g., N38SH)

Choose Magnetization Direction Based on Motion Type

- Static adsorption: Axial magnetization (single-side force)

- Rotating equipment: Radial magnetization (e.g., motor rotors)

- Precision control: Multi-pole magnetization (reduces eddy current loss)

Quick rule: Size by space, grade by scenario, direction by motion.

Usage Strategies for Neodymium Channel Magnets in High-Temperature and Special Operating Conditions

Phenomenon

High temperatures disrupt the alignment of magnetic domains, causing complete demagnetization if the Curie temperature is exceeded, and performance degradation even below it.

Influencing Factors

- Material heat resistance (e.g., NdFeB has low tolerance, SmCo has high tolerance).

- Temperature fluctuations accelerate aging.

Prevention

- Use high-temperature-resistant materials (e.g., SmCo).

- Enhance heat dissipation (heat sinks/cooling fans).

- Avoid overheating during operation.

Standard Pull Force Test Method and Key Considerations

Test Method

Use a calibrated tensile tester with a non-magnetic fixture.

Gradually increase vertical pull force until magnet detaches from the test surface.

Record peak force value as pull force (N or kgf).

Critical Factors

Surface condition: Test plate material/surface finish must match application specs (e.g., steel D36, Ra≤1.6μm).

Contact area: Ensure full contact with zero air gaps.

Separation speed: Maintain 5-10 mm/s steady pull rate.

Precautions

Perform 3-5 repeated tests for averaging.

Demagnetize test plates between trials if testing multiple magnets.

Document ambient temperature (affects NdFeB magnets' performance).

Customization Guide – How to Communicate Efficiently with Suppliers

● Dimensional drawing or specification (with Dimensional unit)

● Material grade requirements (e.g. N42 / N52)

● Magnetization direction description (e.g. Axial)

● Surface treatment preference

● Packaging method (bulk, foam, blister, etc.)

● Application scenario (to help us recommend the best structure)